We have been working on a 2-year project funded by the New York Farm Viability Institute to look at adding biofungicides to the management of two vegetable diseases: cucurbit powdery mildew and white mold. In addition to summarizing results from Year 1 of the trial, previous blog posts also covered some of the details about how to best use the biofungicides we’re testing. During the summer of 2019, we completed our second year of trials. The numbers have all been crunched, and here’s a summary of what we learned. If you want to read all the nitty gritty details, a lengthy full report from Year 2 is available here.

Project goals

During the second year of this project, we wanted to answer a few questions for growers:

- Can you replace some conventional fungicide applications for cucurbit powdery mildew in winter squash with one of three OMRI-listed biofungicides (LifeGard, Regalia, or Serifel) while maintaining disease control, crop quality, and yield?

- Can you get better control of white mold in green beans by Contans prior to planting, and Double Nickel at bloom?

- What are the costs (versus benefits) of using these biofungicides in these ways?

- Can NDVI sensors help us detect disease early? Can they help us detect differences in plant health as a result of using biofungicides?

White mold – what we did

This table summarizes the white mold treatments in green beans. Replicated plots were treated with Contans in the third week of May, prior to planting; Double Nickel when snap beans were at 10% bloom (late June or early July) and 7 days later; both Double Nickel and Contans; or neither. Treatments are summarized below.

| Timing | Non-treated | Contans | Double Nickel | Contans + Double Nickel |

| Pre-plant | – | Contans (2 lb/A) |

– | Contans (2 lb/A) |

| 10% bloom | – | – | Double Nickel LC (2 qt/A) | Double Nickel LC (2 qt/A) |

| 7 days later | – | – | Double Nickel LC (2 qt/A) | Double Nickel LC (2 qt/A) |

White mold – what we saw and what it means

There was very little disease in the white mold trials on either collaborating farm in 2019. This is great news for the collaborating farms, but it means that we couldn’t answer our question about whether using both Contans and Double Nickel in a single season would improve control of white mold. Sarah Pethybridge did three years of efficacy trials with Double Nickel and other OMRI-approved products. In small plot trials with uniform disease pressure Double Nickel was as effective as the conventional fungicides it was compared to in reducing disease. You can read about her results here.

Cucurbit powdery mildew – what we did

We conducted the cucurbit powdery mildew trials on one farm in Eastern NY and on research farms on Long Island and in Western NY, always using the bush acorn squash variety ‘Honey Bear’. This table summarizes the treatments we compared. Essentially, we started with two early biofungicide sprays, then shifted to rotating products when disease was detected. But, in some treatments we replaced the scheduled conventional product with a biofungicide every other week. The biofungicides we looked at were the same as last year: LifeGard, Regalia, and Serifel. We compared these treatments to both a regular conventional fungicide program and a “Conventional + skip” program where we just skipped every other conventional fungicide. And, we included an organic program with traditional OMRI-listed products plus the biofungicides. Important note: Luna Experience is NOT allowed for use on Long Island. We used it in a research plot in order to be able to make comparisons to trials conducted in other parts of the state. You can learn more about fungicide options for managing cucurbit powdery mildew here, and here.

| Date | Non-treated | Conventional | Conventional + skip | Conventional + LifeGarda | Conventional + Regaliaa | Conventional + Serifelb | Organicab |

| ~14 days before disease | – | – | – | LifeGard WG (4 oz/100 gal) | Regalia (2 qt/A) | Serifel

(8 oz/A) |

LifeGard WG (4 oz/100 gal) |

| ~7 days before disease | – | – | – | LifeGard WG (4 oz/100 gal) | Regalia (2 qt/A) | Serifel

(8 oz/A) |

LifeGard WG (4 oz/100 gal) |

| First disease detection | – | Vivando (15 fl oz/A) | Vivando (15 fl oz/A) | Vivando (15 fl oz/A) | Vivando (15 fl oz/A) | Vivando (15 fl oz/A) | MilStop (3 lb/A) |

| +7-10 days | – | Luna Experiencec (10 fl oz/A) | – | LifeGard WG (4 oz/100 gal) | Regalia (2 qt/A) | Serifel

(8 oz/A) |

Serifel (8 oz/A) |

| +14-17 days | – | Quintec (6 fl oz/A) | Quintec (6 fl oz/A) | Quintec (6 fl oz/A) | Quintec (6 fl oz/A) | Quintec (6 fl oz/A) | Suffoil-X (1% v/v) |

| +21-24 days | – | Vivando (15 fl oz/A) | – | LifeGard WG (4 oz/100 gal) | Regalia (2 qt/A) | Serifel

(8 oz/A) |

MilStop (3 lb/A) |

| +28-31 days | – | Luna Experiencec (10 fl oz/A) | Luna Experiencec (10 fl oz/A) | Luna Experiencec (10 fl oz/A) | Luna Experiencec (10 fl oz/A) | Luna Experiencec (10 fl oz/A) | Serifel (8 oz/A) |

| +35-38 days | – | Quintec (6 fl oz/A) | – | LifeGard WG (4 oz/100 gal) | Regalia (2 qt/A) | Serifel

(8 oz/A) |

Suffoil-X (1% v/v) |

a LifeGard and Regalia were tank mixed with Nu Film P (1 qt/100 gal)

b Serifel was tank mixed with EcoSpreader (4 fl oz/100 gal) when applied at spray volumes of 30 to 40 gal/A.

c Luna Experience is not allowed for use on Long Island. The Long Island trial was conducted on a research farm.

We summarized disease severity on multiple dates over the season by calculating the area under the disease progress curve (AUDPC). This value describes with a single number how quickly disease developed and how bad it got. We also measured NDVI using a GreenSeeker as a way to quantify how green and healthy the leaves were. At the end of the season, we collected yield and Brix data.

Cucurbit powdery mildew – what we saw

Not surprisingly, there was some variability among sites. But at two sites disease severity was not statistically different when we compared the standard weekly conventional fungicide program to skipping every other fungicide spray. This was disappointing, since we were expecting more severe powdery mildew from extending the spray interval, providing room for the biopesticides to improve control. However, in the Long Island trial, although powdery mildew was more severe when the spray interval was extended, applying a biopesticide during the skip week did not improve control.

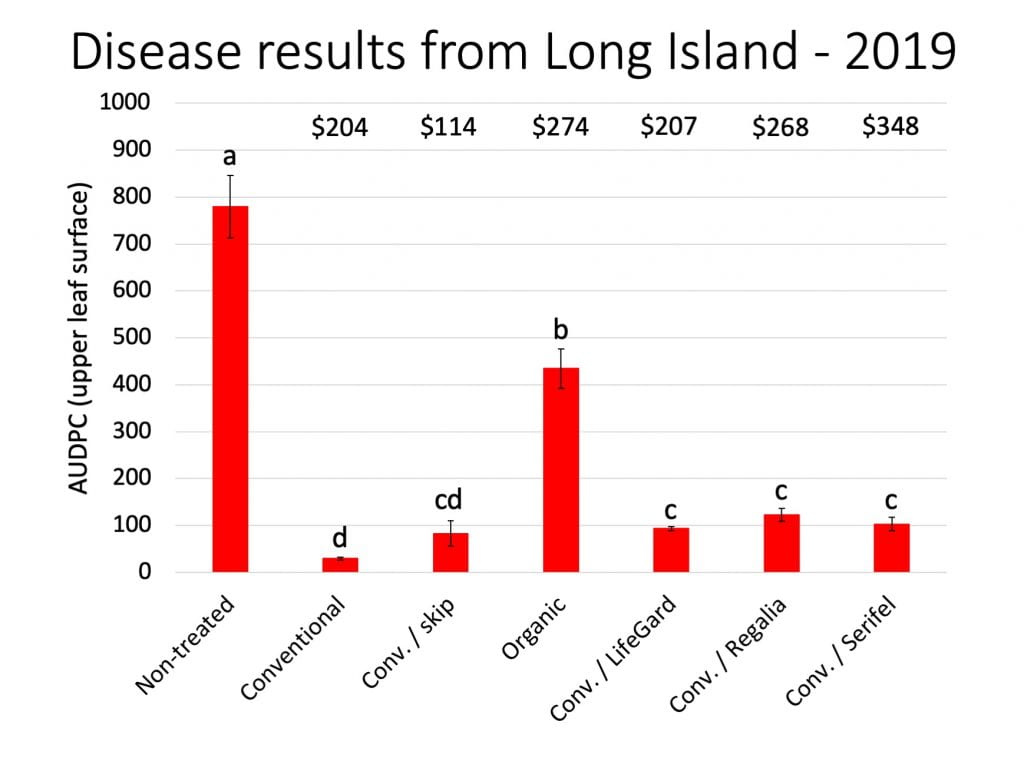

For the most part, replacing alternate conventional fungicides with biofungicides resulted in disease levels that were somewhere between the conventional fungicide program and the non-treated control. At two sites LifeGard and Serifel performed slightly better than Regalia. To keep this post a reasonable length, we’re only showing results from the Long Island trial, here.

The above graph shows a summary of disease on the upper leaf surface over the whole season. We’re not reporting the data here, but if you look at disease ratings on individual dates or on the lower surface of the leaves, skipping every other fungicide or alternating conventional fungicides with biofungicides were not as good as the weekly conventional fungicide program.

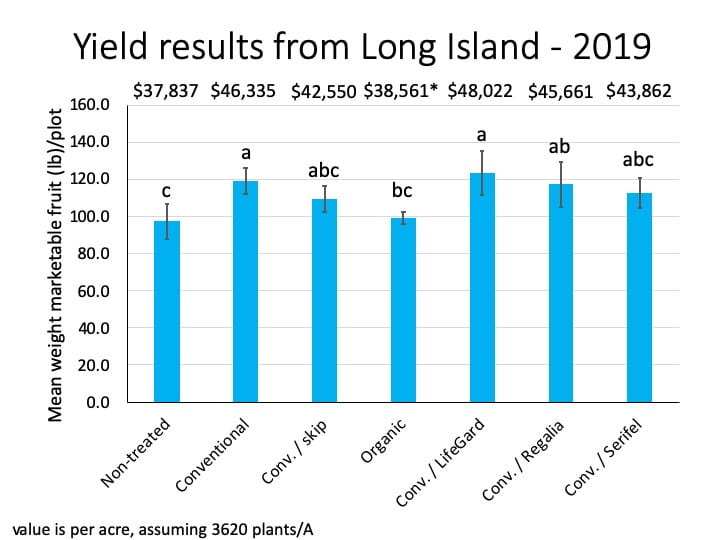

At all three sites, yield was not statistically different when we compared the standard weekly conventional fungicide program to skipping every other fungicide spray. There were no statistically significant differences in yield in the Eastern NY trial, and few differences in the Western NY trial. In both trials, when Regalia was alternated with conventional fungicides the yield was slightly but not significantly lower than the conventional/LifeGard and the conventional/Serifel treatments. In the Long Island trial, only the full conventional treatment and treatments that included LifeGard or Regalia had significantly higher yields than the non-treated control. Again, we’ll show just the data from Long Island to keep this story briefer.

Our data did not suggest that NDVI readings taken with the GreenSeeker were a good replacement for visual scouting, or that this was a good tool for detecting differences in plant health among treatments. When NDVI readings differed among treatments, powdery mildew symptoms were readily evident. The most substantial differences in NDVI values among treatments were in the Long Island trial, where both the non-treated control and the organic treatment had much lower average NDVI values over the season.

On the whole, Brix were unaffected by powdery mildew management strategy. The only statistically significant differences in Brix values among treatments were in the Eastern NY trial where the conventional/LifeGard treatment had significantly lower Brix than the conventional/Serifel treatment.

Cucurbit powdery mildew – what it means

When the full conventional fungicide program didn’t result in statistically better disease control than skipping every other spray at 2 of the 3 sites, it’s not possible to say whether or not the biofungicides were good replacements for conventional fungicides against powdery mildew. However, they did not prove to be in the Long Island trial. Our results did not suggest that measurement of NDVI values with a GreenSeeker should replace visual scouting for cucurbit powdery mildew.

Depending on the trial location (and accompanying variations in spray schedules and rates), replacing some conventional fungicides with biofungicides ranged from slightly less expensive than the full conventional program to more than twice the cost. Although in most cases there were no statistically significant differences in the value of the crop between the conventional/biofungicide programs and the full conventional program, the numerical value of the marketable crop ranged from being slightly higher (LifeGard alternated with conventional fungicides on Long Island) to lower (all other biofungicide treatments). Again, the lack of statistically significant differences between the full conventional spray program and the conventional spray program with skips in 2 of the 3 trials makes any conclusions about the economics of replacing some conventional fungicides with biofungicides, tentative, at best. There’s a lot of room to fine-tune incorporation of biofungicides into spray programs to maximize cost effectiveness.

Recall from last year’s results that we did not detect any benefit from adding biofungicides to a full cucurbit powdery mildew fungicide program. So if you’d like to use biofungicides for cucurbit powdery mildew, replacing a conventional fungicide application or two is probably a better way to go. If you’ve tried this, we’d love to hear how it worked for you!

Remember that the information in this post is not a substitute for a pesticide label. The label is the law, and you must read and follow the label of any pesticide you are using. It is your responsibility to use pesticides legally.

This post was written by Amara Dunn (NYSIPM) and Meg McGrath (Plant Pathology & Plant-Microbe Biology, School of Integrative Plant Science, Cornell University). Thank you to the New York Farm Viability Institute for funding.