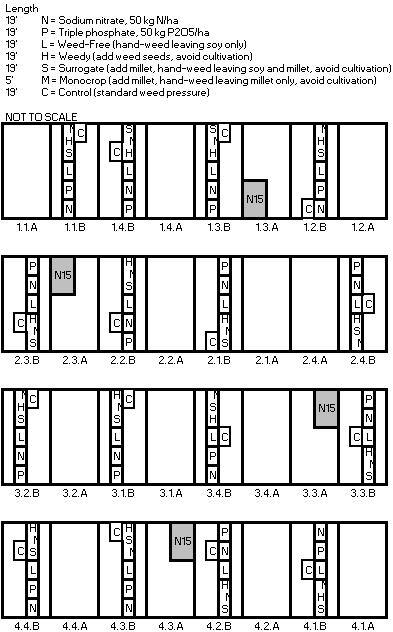

The last experiment I worked on was the Musgrave Organic Soybean Silage (MOSS) experiment. The head person on this project was a new grad student, Kiera Crowley. The experiment aims to compare different winter cereal management in corn and soybean rotation. The winter cereal used in all of the management experiments was cereal rye. There are four different winter cereal management’s being tested in this experiment: a no-till with the cereal rolled and crimped, a plow down, a management where the rye is cut for silage and what’s left gets plowed under, and a no cover crop management. Kiera plans on running multiple tests on the experiment to see if these different managements are having any effect. I helped execute soil property tests and water infiltration tests. In addition to that, Kiera is analyzing weed suppression and yield.

From the last post, you can see that I have done some soil sampling before. We took sixteen samples from each plot and there are twelve plots. We took these samples in order to analyze the soil properties. Bigger soil core samplers were used so we could examine aggregate stability. Four samples were taken from each plot. When taking the soil cores for aggregate stability, it was a more challenging and time-intensive process than regular soil sampling. The soil core had to be 6 inches and the diameter of the sampler was greater than 2 inches. In order to get the sampler down 6 inches, it took force and some finagling. After taking the sample out of the ground, we had to be careful not to disturb the soil too much. The test was for aggregate stability which is a factor of soil structure, so the less disruption of the soil structure, the better. All the soil was taken back to the lab for processing. The processing of the samples dealt with chemistry. I was able to help with some of the processing of the mineralizable carbon test. Kiera had done all of the prep work and my job was just to extract the mineralizable carbon.

The second piece of the experiment I worked on was the water infiltration tests. The water infiltrometer is a device used to measure the water infiltration (the process by which water flows into the soil).

Base of the Infiltrometer

Infiltrometer all ready to go

Recording results from Infiltrometer

Infiltrometers let you fix a rate of water dispersal onto soil. Infiltrometers can be used different ways depending on what you are looking for. We were interested in time until runoff. This involved recording the height of the water in the infiltrometer every minute. This way you can find the rate for each minute and can check to make sure it is staying consistent. This process is continued until there is runoff. After runoff had occurred, we recorded the amount of water that was used and the time it took to runoff. Working with the water infiltrometers was a very interesting and educational experience. The first time we tried to do water infiltration it didn’t go as planned. The rate is meant to stay consistent the whole time. While we had some successful infiltrations, during many of the infiltrations the rate kept decreasing and with some we never got runoff. We weren’t even able to finish all of the plots and this is very important because all of the samples should be taken within the same day. After some clarification and advice from a few people, we made some adjustments. The second time running the water infiltration tests were much more successful. The rates were staying consistent and we were able to finish within one day.