Several NMSP team members made the quick drive out the Musgrave Research Farm for their annual field day earlier this week. It was really exciting to see how scientists communicate the value of their ongoing projects with both other researchers and the general public. There were a lot of cool speakers and a great lunch featuring Cornell Chicken Barbecue Sauce.

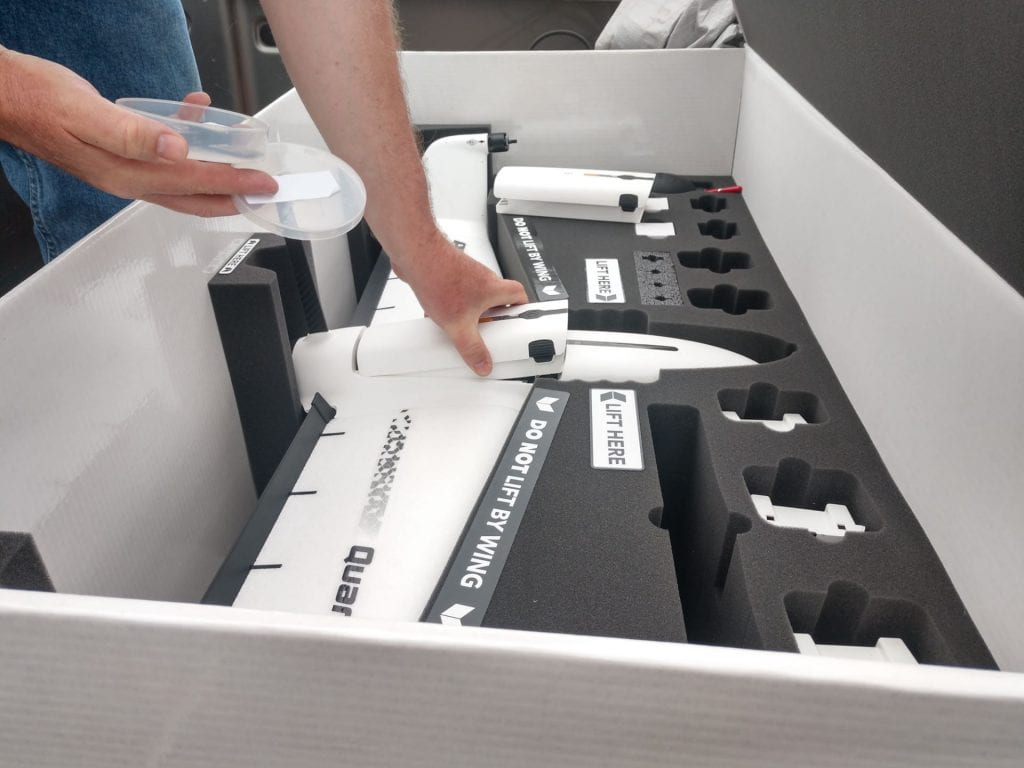

Pictured: Kernza®️ intercropped with nitrogen-fixing red clover. This trial aimed to see whether or not farmers could avoid using expensive nitrogen fertilizer while still harvesting a strong grain crop.

One of the most interesting plots was the full field of intermediate wheatgrass. This crop goes by the tradename Kernza® and is known for both its exceptionally large root system and its ability to perenially produce bread quality grain. This means that the need for tillage is greatly limited, and the long roots are believed to support healthy soil development even on marginal land. Unfortunately, low yields have been a large challenge with this crop. The trial at Musgrave found that the crop stand gets so thick after a few years of establishment that grain yield is limited by self-competition. The researchers were able to relieve some of this pressure by using strip tillage to lower the amount of plants per acre. This seemed to be very effective at increasing yield, but not to the point that Kernza® was competitive with wheat on a pounds-per-acre basis. However, Kernza® also provides high quality straw forage for livestock which could make it a suitable crop for farmers with land at risk for soil erosion. I will be very curious to see how researchers continue to develop these cropping systems in the future, especially if carbon marketing comes into play for American farmers.