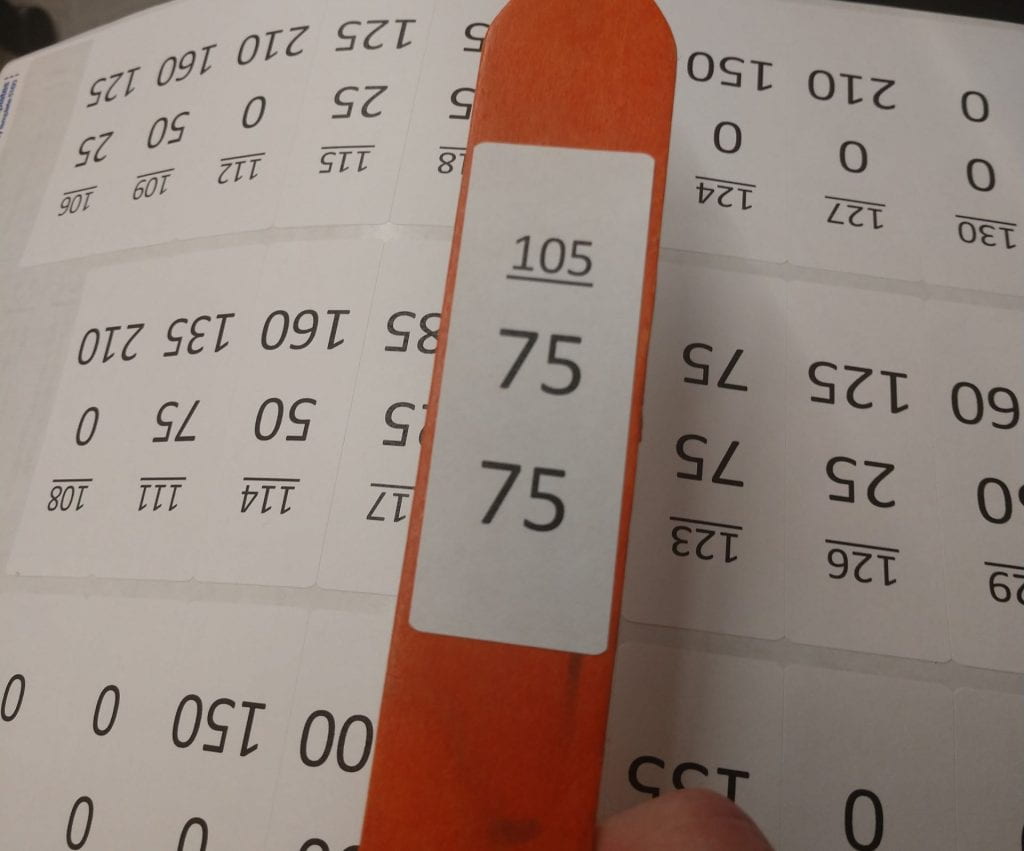

With the improved weather over the weekend, we were able to get into the field and place some stakes for nitrogen fertilizer trials this week! I attached a picture of the stakes below. They will be used as a reference for field treatments along with GPS coordinates to be taken at a later date. To place stakes, Greg and I followed a map indicating where each plot was located in the field. Plots have randomized locations over several trials in order to avoid environmental impacts from certain field sections influencing the final results.

Top: Plot or treatment number

Middle: Pre-plant nitrogen treatment in pounds per acre

Bottom: Sidedress nitrogen treatment in pounds per acre

The trial features rye terminated at several different stages along with different volumes of both pre-plant and sidedress nitrogen fertilizer. Cover crops like these are important because they can improve soil health and increase soil organic matter, both of which provide a ton of value to New York State farmers. It was really cool to see the corn poking out from under the rye stubble, especially considering the difficult planting and field work conditions that farmers have faced this year.