This week I got to spend even more time with extension agents in the field! I drove up to North Country to spend some time with Mike Hunter, a Field Crops Specialist with the CCE North Country Regional Ag Team. Mike led a field day that morning at some of his soybean herbicide plots. Although most weeds are still pretty well controlled by glyphosate, Mike is working hard to develop strategies for farmers to deal with the relatively new challenges presented by herbicide resistant weeds. Tall waterhemp, Palmer amaranth, and glyphosate-resistant marestail are all large threats to crop production in this region of New York State.

Mike took me out to a couple of farmer’s fields to look for possible signs of herbicide-resistant weeds. This soybean field has already been sprayed with glyphosate, but the marestail is is rampant! If the marestail goes to seed, it will be very difficult to control here for years to come.

Maintaining good relationships with local farmers is also an important part of Mike’s work. He has to be able to communicate the results of his own test plots along with other new science in a way that makes sense and is applicable to each farmer that he works with. One example of this is Reed Haven Farms. The farm produces around 1200 acres of crops to feed their dairy herd. Getting to tour their farm gave me an opportunity to see how technology and science can help farms of all sizes.

At Reed Haven, most of the cows are milked by robotic milkers. This cuts down on long term labor costs and volatility, allowing the farmers to focus more on other management aspects of the farm. Pictured here, an alleyway has also been neatly swept by a robotic feed-pusher.

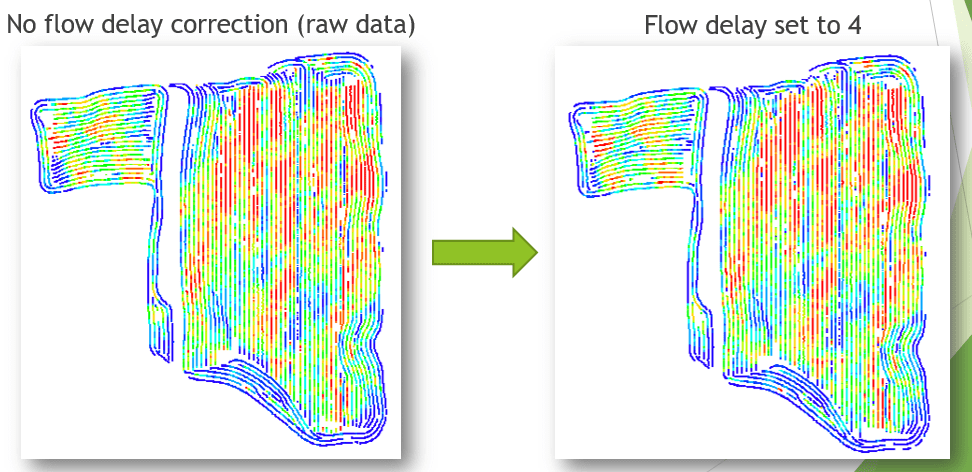

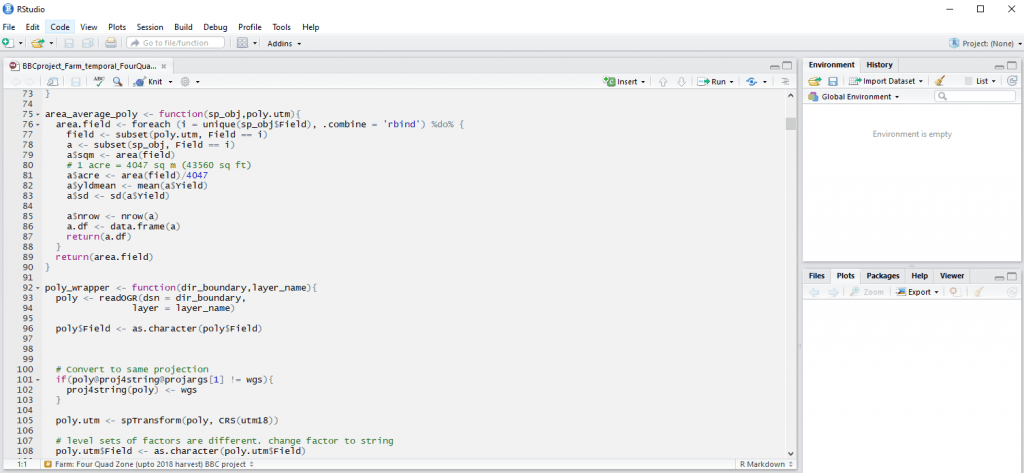

Using laser guidance to attach milk cups to the cow, the robotic milker lowers stress for animals and has helped the farm achieve low somatic cell counts. The cow is able to quickly and comfortably be milked out on her own schedule. Tons of data gets collected from each cow, including the number of chews per day as well as the amount of milk delivered from each quarter of the udder. I posted a video of the milker in action below. The farm currently has 3 milking robots, with the infrastructure in place to add 2 more milkers to their main barn soon.