Martin L. Battagliaa, Quirine M. Ketteringsa, G. Godwina, Karl J. Czymmeka,b

a Nutrient Management Spear Program, b PRODAIRY, Department of Animal Science, Cornell University

Introduction

Conservation tillage practices and incorporation and injection of manure have increased in New York State over the last 20 years. In the future, it is expected that dairy farmers will need to make significant further progress toward no-till practices to minimize soil erosion losses and maximize soil health and carbon sequestration. Compared to surface application of manure, incorporation and injection can reduce ammonia volatilization, odor emissions and nutrient losses, particularly phosphorus (P), in water runoff. However, shallow incorporation of manure with an aerator tool or similar full-width tillage implements, while effective at retaining nitrogen (N) and P (Place et al., 2010), does not meet no-till practice standards as defined by USDA-NRCS. Injection of manure is only compatible with no-till and reduced tillage if low disturbance equipment is used. One central question is: are conservation tillage practices, including no-till planting and zone building, compatible with systems where manure is spring-injected in New York.

Field studies

Two types of studies were conducted on dairy farm fields in western New York. The first study (2012-2013) evaluated the impact of zone tillage depth (0, 7 and 14 inches). This study was completed on one field in 2012 and two fields in 2013. An aerator was used for seedbed preparation. The second study (2014-2016) evaluated three intensities of conservation tillage, including no-tillage, reduced tillage (aerator without zone tillage), and intensified reduced tillage (aerator plus zone tillage at 7 inches depth). This study was conducted on two fields each year.

Two types of studies were conducted on dairy farm fields in western New York. The first study (2012-2013) evaluated the impact of zone tillage depth (0, 7 and 14 inches). This study was completed on one field in 2012 and two fields in 2013. An aerator was used for seedbed preparation. The second study (2014-2016) evaluated three intensities of conservation tillage, including no-tillage, reduced tillage (aerator without zone tillage), and intensified reduced tillage (aerator plus zone tillage at 7 inches depth). This study was conducted on two fields each year.

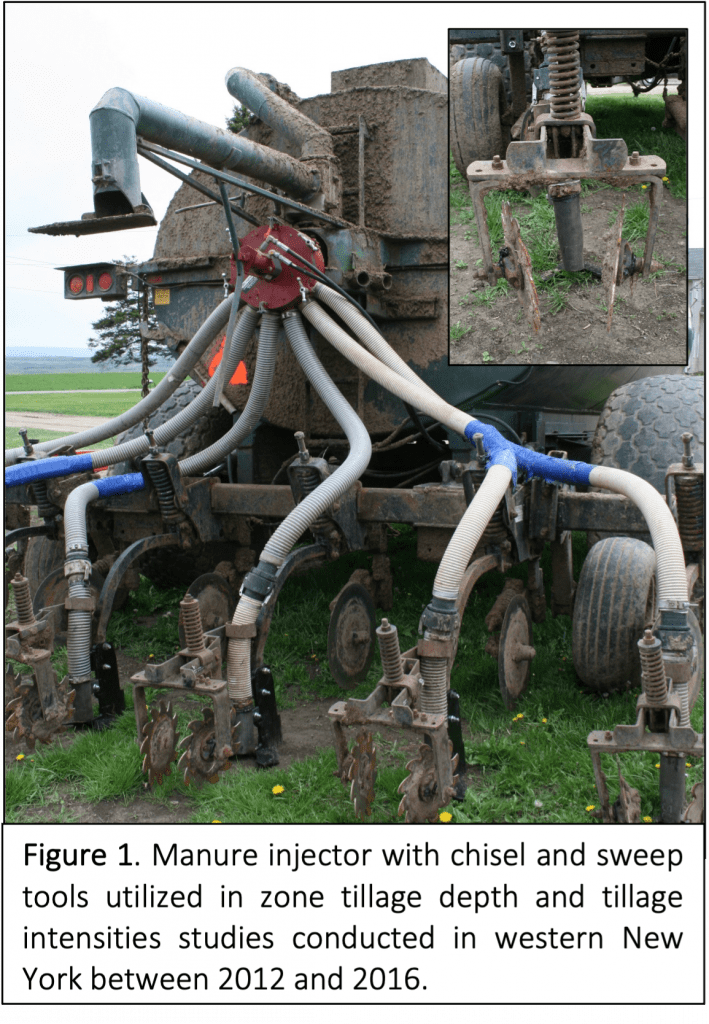

All fields had a zone tillage and a winter cereal cover cropping history of more than 10 years. Fields were in a dairy rotation of typically 3-4 yr corn alternated with 3-4 yr alfalfa/grass. Liquid manure was used as the primary source of soil fertility. It was injected (6-inch depth; 30 inches between injection bands) in March at a rate of about 13,000 gallons per acre (2012 through 2015) or 8,000 gallons per acre (2016) using a manure injector with chisel and sweep tools (Figure 1). Average total N content in manure ranged from 20 to 25 pounds of N per 1000 gallons. Manure P content ranged from 5 to 11 pounds of P2O5 per 1,000 gallons, while solids content varies from about 5 to 10%.

In both types of studies, zone tillage was performed in late April using an 8 row (30 inch) zone builder with subsoiler shanks and a 20-foot wide aeration tool set at a 15 degree angle pulled in tandem. Corn was planted at 15-inch corn row spacing at a rate between 34,000 and 35,000 seeds per acre between April 30 and May 13. No sidedressing of N was done given practical limitation of 15-inch corn row spacing. Each year, we measured early growth parameters (plant biomass, leaves per plant, stand density, and plant height at V5), and took soil samples at V5 that were analyzed for the pre-sidedress nitrate test (PSNT). At harvest we took corn stalks and analyzed them for the corn stalk nitrate test (CSNT), determined silage yield and dry matter content as well as forage quality parameters including crude protein (CP), acid detergent fiber (ADF), and neutral detergent fiber (NDF).

Results

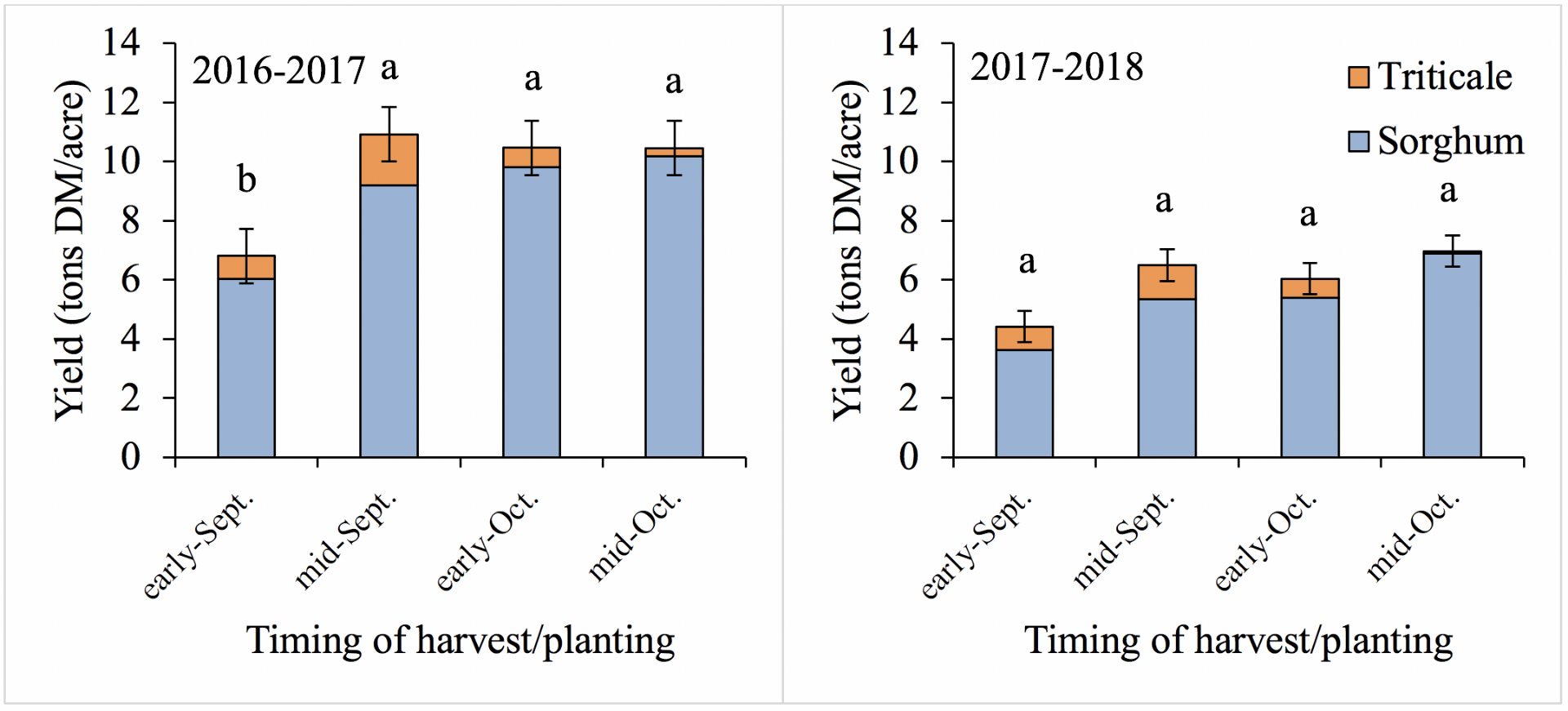

Average plant density at V5 ranged between ~31,600 and 32,700 plants per acre (between 90 and 96% of the seeding rate). Reduced tillage and even omitting tillage altogether did not impact early corn silage stand density (Table 1).

In both types of studies, and for all fields, the PSNT-N exceeded 21 ppm NO3-N, indicating sufficient N from manure and soil organic matter mineralization. The PSNT results also indicate no impact of tillage practice or depth on mid-season N availability (Table 1).

Silage yield averaged about 25 tons per acre (at 35% dry matter) in the tillage depth study, with 7.8% CP. In the tillage intensity studies, yields averaged about 23 tons per acre with 7.3% CP. The results should not be compared between the two types of studies as trials were conducted on different fields and across different growing seasons. Tillage depth or intensity did not impact yield or CP content in either of the studies (Table 1).

The CSNT-N ranged between 3,235 and 3,589 ppm NO3-N in the zone tillage depth, and between 2,315 and 2,753 ppm NO3-N in the tillage intensity study, above the 2,000 ppm NO3-N optimum range. Zone tillage depth and different tillage intensities did not impact CSNT-N and both PSNT-N and CSNT-N show N was not limiting plant growth (Table 1).

Conclusions and Implications

All types of tillage systems and depths performed equally well in terms of plant growth, N availability, corn silage yield and quality suggesting that reduced tillage and no-till can both be viable options to more intensive tillage for this farm. Results might be different for fields with limited history of zone building and other efforts to improve soil health. We conclude that at this farm that has made significant efforts to adopt soil health practices, manure injection followed by no-till planting or zone building can sustain yields and conserve N. No-till planting has the additional benefit that it reduces soil disturbance, risk of P runoff, as well as tillage-associated fuel, equipment, and labor costs.

Additional Resources

-

- Place, A., Q.M. Ketterings, G. Godwin, J. Lawrence, B. Aldrich, P. Barney, and T. Kilcer (2010). Shallow incorporation of manure minimizes soil disturbance and conserves nitrogen. What’s Cropping Up? 20(3): 3-5.

Full Citation

This article is summarized from our peer-reviewed publication: Battaglia, M.L., Ketterings, Q.M., Godwin, G., Czymmek, K.J. 2021. Conservation tillage is compatible with manure injection in corn silage system. Agronomy Journal. https://doi.org/10.1002/agj2.20604 (in press).

Acknowledgements

In memory of Willard DeGolyer, whose dedication to on-farm research inspired us all. This study was funded by the New York Farm Viability Institute (NYFVI), a USDA Conservation Innovation Grant (69-3A75-17-26), supplemented by federal formula funds. We thank the owners and the farm crew for their collaboratively work and dedication to the success of this research over the 5 years where the field studies were conducted. For questions about these results, contact Quirine M. Ketterings at 607-255-3061 or qmk2@cornell.edu, and/or visit the Cornell Nutrient Management Spear Program website at: http://nmsp.cals.cornell.edu/.

In memory of Willard DeGolyer, whose dedication to on-farm research inspired us all. This study was funded by the New York Farm Viability Institute (NYFVI), a USDA Conservation Innovation Grant (69-3A75-17-26), supplemented by federal formula funds. We thank the owners and the farm crew for their collaboratively work and dedication to the success of this research over the 5 years where the field studies were conducted. For questions about these results, contact Quirine M. Ketterings at 607-255-3061 or qmk2@cornell.edu, and/or visit the Cornell Nutrient Management Spear Program website at: http://nmsp.cals.cornell.edu/.

![Plant density and pre-sidedress nitrate test (PSNT) at V5, and corn stalk nitrate test (CSNT), silage yield [35% dry matter (DM)], crude protein (CP), and acid and neutral detergent fiber (ADF, NDF).](https://blogs.cornell.edu/whatscroppingup/files/2021/02/Conservation-tillage-Table-1-1024x457.png)