Sunoj, S.1, J. Cho1, J. Guinness2, J. van Aardt3, K.J. Czymmek1,4, and Q.M. Ketterings1

1Nutrient Management Spear Program, Department of Animal Science, 2Department of Statistics and Data Science, and 4PRODAIRY, Department of Animal Science, Cornell University, Ithaca, NY 14853; 3Chester F. Carlson Center for Imaging Science, Rochester Institute of Technology

Introduction

Yield maps can help farmers identify high and low yielding areas in a field and customize management practices to maximize return on investment. Currently, most yield monitor systems on choppers and combines record yield and GPS location at 1-second intervals. With properly calibrated systems, and once data generated by these systems are cleaned of errors, accurate yield maps can be generated. However, calibration and data cleaning are required as extra steps prior to yield mapping, while sensors are expensive and can break during harvest, without the opportunity to redo the data collection. Approaches to estimate yield that reduce the risk of data loss, are less time consuming, and can be used by a larger number of farmers therefore could be beneficial. Here we report on a study using drones (commonly called “unmanned aerial systems” or UAS) to estimate yield at the subfield level.

Timing of N sidedress and UAS flights

Sidedress N treatments – The experiment was conducted at the Musgrave Research Farm in Aurora, NY in 2019. All N treatments received starter N (30 lbs N per acre). Six N treatments were implemented including zero N (NoN – only starter), N rich (NRich; 300 lbs N per acre at planting), and sidedress applications (180 lbs N per acre applied) at V4, V6, V8, or V10.

UAS flights – Weekly UAS flights (total of 12 flights) were done between VE and R5 using the QuantixTM mapper from AeroVironment Inc. The UAS payload consists of two cameras, one for color imagery (red, green, and blue bands) and one with a near-infrared (NIR) band. The reflectance values were used for calculating “vegetation indices”, which typically are used to highlight specific vegetation features or conditions. Although six different vegetation indices were tested, we only report here on models derived using the normalized difference vegetation index (NDVI), which was best-suited for yield estimation. NDVI is a combination of the red and near-infrared bands.

Results

Did a Delay in Sidedressing Impact Yield?

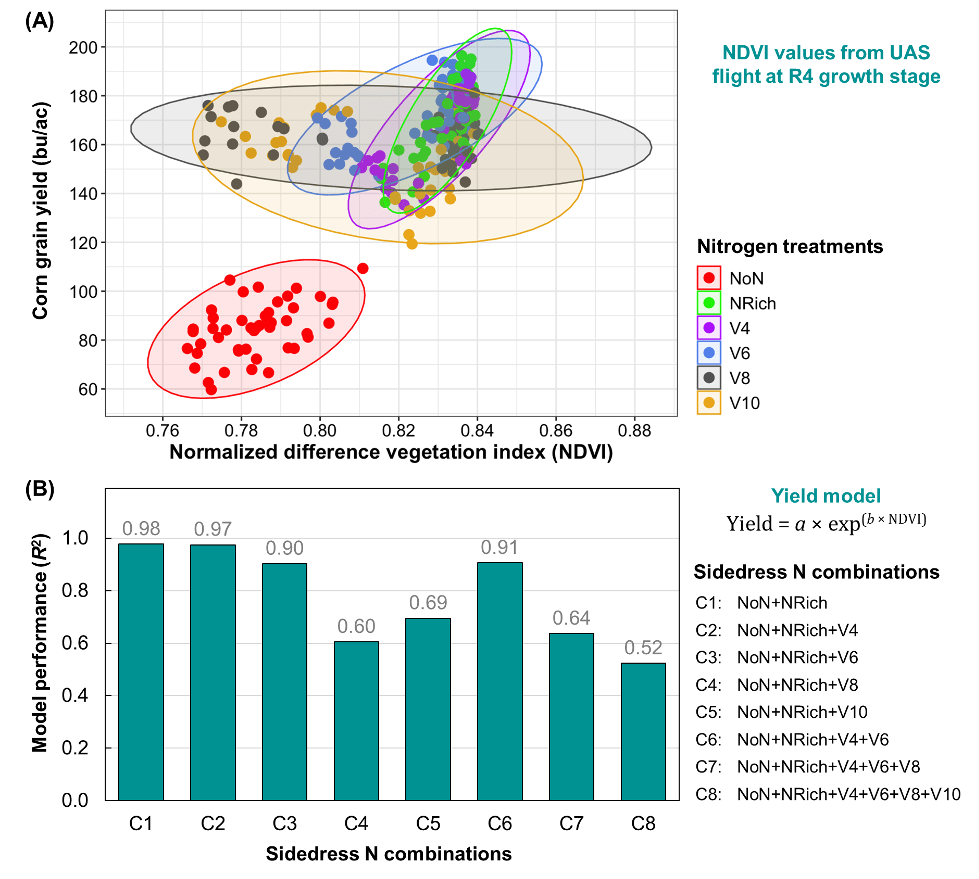

All N treatments that received more than just starter N produced higher yields (Figure 1A), with NRich and sidedressing at V4 and V6 producing the highest yields (~170 bushels per acre) and the NoN treatment producing the lowest yields (85 bushels per acre). Delay in sidedressing to V8 and V10 resulted in lower yields. These results were consistent with N sidedress experiments across four years at the same location (Link).

Did Timing of Sidedressing Impact Yield Model Accuracy?

The timing of N sidedress application had not just an effect on yield, but also on NDVI reflectance when sensed at the R4 growth stage (Figure 1A). Earlier sidedress N application (up to V6) produced a narrow range of NDVI values, while delaying the N sidedress application produced more variable NDVI signals (e.g., V8 and V10 in Figure 1A).

The performance of yield estimation models (Figure 1B) showed that models that used data from plots that were sidedressed at or before V6 did well (R2 > 0.90), whereas inclusion of data from plots that were sidedressed at V8 or V10 were much less reliable (R2 < 0.68). These findings suggest that estimation of yield for fields that were sidedressed later than V6 are much less reliable, even with inclusion of NoN and NRich NDVI data.

Does Timing of Flight in the Season (Growth Stage) Impact Yield Model Accuracy?

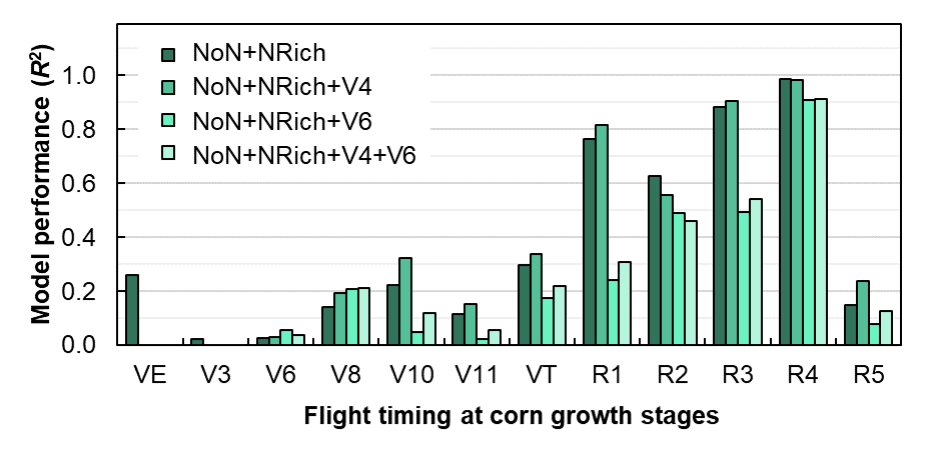

Flights at the R4 growth stage resulted in reliable models, as long as sidedressing took place at or before V6. But what about flying earlier in the season? Data shown in Figure 2 indicate a much lower estimation accuracy at all vegetative growth stages (up to VT) and after R4 (Figure 2). At R5 the canopy started to turn yellow and much of the reflectance signals were not reliable for yield estimation. The lower performance at R2 was attributed to cloudy conditions during the flight, highlighting one challenge with the use of passive sensors to capture NDVI. Our results suggest that flying on a sunny day, when corn is between R1 and R4, gives us the best yield estimation models.

Conclusions and Implications

Yield estimation using drones is a promising approach provided we implement the following management strategies: (1) Avoid delay in sidedressing – Sidedressing after V6 not only reduced corn grain yield, but also produced variable NDVI values, resulting in poor estimations of corn grain yield; (2) Fly the drone between R1 and R4 – After R4, the canopy starts to turn yellow, which makes it unsuitable for yield estimation; and (3) Avoid cloudy days for flights – Flying on cloudy days can impact the images collected and the accuracy of yield estimation models derived from the imagery. Ongoing research at the NMSP is exploring an approach of scaling this work to larger fields and developing yield estimation models that can be applied across farm fields and different farms.

Full Citation

This article is summarized from our peer-reviewed scientific publication: Sunoj, S., J. Cho, J. Guinness, J. van Aardt, K.J. Czymmek, and Q.M. Ketterings (2021). Corn Grain Yield Prediction and Mapping from Unmanned Aerial System (UAS) Multispectral Imagery. Remote Sensing, 13(19), 3948. https://doi.org/10.3390/rs13193948

Acknowledgements

This research was funded with federal formula funds. We thank Greg Godwin for flying the Quantix drone and Paul Stachowski, farm manager of the Musgrave Research Farm at Aurora, NY, for help with field management. We also thank the many NMSP team members for help with harvest and sample processing over the years. This research was funded in part with Federal Formula Funds and through grants from the New York Farm Viability Institute (NYFVI) and New York State Department of Environmental Conservation (NYDEC). J.G. received support from the National Science Foundation under grant No. 1916208. For questions about these results, contact Quirine M. Ketterings at 607-255-3061 or qmk2@cornell.edu, and/or visit the Cornell Nutrient Management Spear Program website at: http://nmsp.cals.cornell.edu/.

This research was funded with federal formula funds. We thank Greg Godwin for flying the Quantix drone and Paul Stachowski, farm manager of the Musgrave Research Farm at Aurora, NY, for help with field management. We also thank the many NMSP team members for help with harvest and sample processing over the years. This research was funded in part with Federal Formula Funds and through grants from the New York Farm Viability Institute (NYFVI) and New York State Department of Environmental Conservation (NYDEC). J.G. received support from the National Science Foundation under grant No. 1916208. For questions about these results, contact Quirine M. Ketterings at 607-255-3061 or qmk2@cornell.edu, and/or visit the Cornell Nutrient Management Spear Program website at: http://nmsp.cals.cornell.edu/.