My final weeks at Hosmer Winery went by swiftly. In these last couple of weeks I worked in the tasting room with my fellow employees. As the days seemed to pass by more quickly, I began to consider the organization from two stand points: the business and the people that made it possible. This blog entry touches on the monetary considerations of Hosmer’s operation and the next entry focuses on the people that seek work within the whole. It is important to consider the businesses and the people who make a living in each to reflect on my coming career goals.

I guess the most appropriate way of starting is in the vineyard. Known legally as Patrician Verona Inc, this was the oldest and, can be considered a foundation for the two other business entities found at Hosmer. The vineyard was created in the late 70s when Tunker had returned home from school. A recent graduate of the Cornell pomology program (unfortunately, the Viticulture program was not around back then), Cameron planted some of the first Cabernet Franc and Riesling vines, on Cayuga Lake. The age that vines grow often determine how healthy and productive they are, the older the better in some sense, leading to increased quality ingredients in the wine and a major marketing advantage over the years.

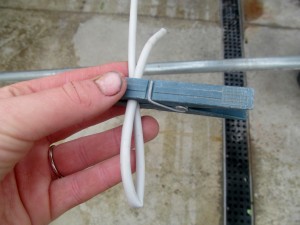

Back then, as it remains today, this was no easy feat. To start a vineyard, it took tens of thousands of dollars in preparation, construction materials, and a large amount of labor to start with just a few acres. Some of the costs include leveling and prepare the soil, installing tile drainage, purchasing and planting the one-year old vines, and over the next couple of years, building a trellis system and caring for the vines. Gerald White, the Emeritus faculty member at Cornell has a fantastic article about the costs of establishing a vineyard (http://dev.senecacountycce.org/wp-content/uploads/2013/06/Cost-to-Establish-Produce-Vinifera-Grapes.pdf).

The real kicker of it is that, despite investing much time and energy into the newly planted vines, the Hosmers could only expect to have a harvest three years after they had first planted the vines and only turning a profit a couple of years later. According to several estimates on the subject, it will typically take more than 7 years to get back your investment of a few acres of vineyard with interest. It may have taken many years and many loans to get the vineyard up and running, but Hosmer set himself up perfectly for the next business, a winery. With a decade of establishing a name for great fruit quality and management, building a good line of credit, and having a reliable supply of high quality grapes every year, Hosmer couldn’t have been in a better place to start a winery.

Regardless, opening a winery is not without significant investment in equipment and time. While equipment and ingredients and storage area are just the beginning of the monetary investment before beginning, nearly a year is typically required to create and age many marketable wines. While much initial investment in equipment is required, the issue of cash flow is essential even once a winery is established. The seasonality of wineries means that there are often large purchases of items like grapes, bottles, and additives. Then, there is the issue of selling the wine to make the whole process even worth investment.

Purchasing wine bottles is quite the cash flow issue to tackle. Each stack of 100 cases costs $5,000.

Today the sales, distribution, and overall marketing of Hosmer’s wines are done about half by Southern Wine and Spirits Distributors and half by the Hosmer tasting room. Southern Wine allows Hosmer to sell much more wine and functions to spread Hosmer’s image and reputation further than it might have gone otherwise. Meanwhile, Hosmer’s own tasting room serves to connect customers to the region, the farm, and the family that makes and, essentially is, the Hosmer brand. A tasting room holds a place for loyal customers to come, but works harder to create loyalty within its customer base. While Hosmer sells its finished wine to its distributor, it is at a lower price than at the tasting room, reducing total possible revenue but simultaneously reducing the cost of sales. The tasting room allows for a higher price of wine but incurs steeper costs, especially for employment which can easily make up more than one third of the costs in tasting rooms around the finger lakes. As a result, the profits per unit of wine may be higher by selling through either the distributor or the tasting room. However, the business as a whole makes up from the “potential lost profits” by diversifying potential sales

Wine can sit and age for months or years, but if it does not get sold on time at a certain price, all the efforts that went into it are without reward. This is one of the risks distributors minimize for a winery.

avenues and customer touch points.

Having the three business entities (vineyard, winery, and tasting room/distribution) has, in essence decreased the risks of of each separate entity and created a synergy(and I only use this word as it is strictly defines and not to sound like the stereotype of a motivational speaker). It is interesting, however, that many of the benefits of this “more than the sum of its parts” model is created by customer perception. If people truly believed that terrior or any permutation of local favoritism translated to a better experience, then they would pay less for the wine. If the value of the wine and the grapes depended less on locality and reliability, then some of the monetary benefits of Hosmer’s business model would fade and it might be more desirable to have only one of the three business sections.Luckily, there is always more than monetary considerations when running a winery as a business. Luckily, happiness, comfort, and general human considerations are the real reasons why a business such as Hosmer exists as it is.