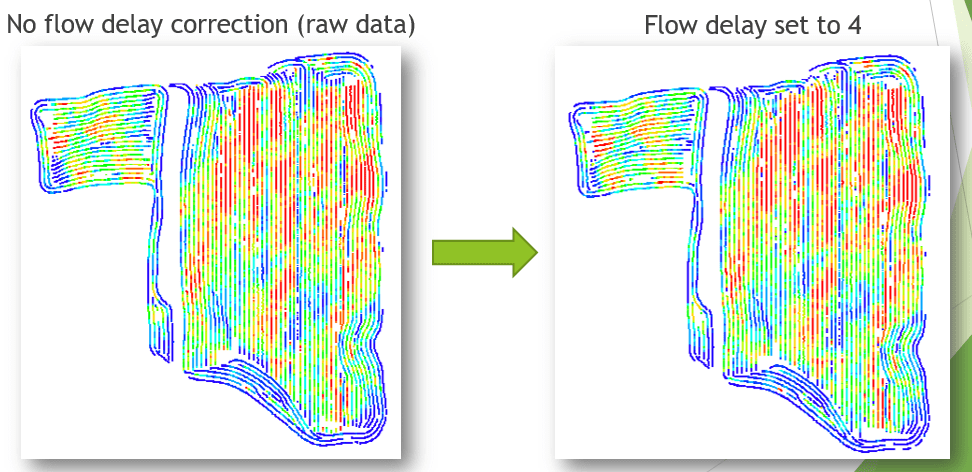

This week, several technicians from a NYS digital agriculture company came in for a yield cleaning training session. This was the first time that I have had a major role in a training session so I was a bit nervous. Using Yield Editor, I walked one technician through the initial settings selection process. There are 4 distinct settings used by Yield Editor to clean harvest maps. Flow delay (as pictured above) is caused by the gap in time between the actual harvest of the crop and the moment when the crop is massed by a sensor. Moisture delay is caused by a similar issue, and is especially important when cleaning silage data (as the moisture of silage is significantly higher and more variable than corn grain moisture). Start Pass Delay and End Pass Delay are both caused by the slowing down and speeding up of the harvester at the edge of the field, which often leads to unreliable yield data.

This is an image pulled from a PowerPoint presentation that I created to help farm consultants learn the data cleaning process. As more and more farms in New York State get yield monitors on their corn harvesters, it will become increasingly important for consultants to feel confident working with that data.

By using both the Automated Yield Cleaning Expert (a Yield Editor feature that estimates the proper delay settings) and a more guess-and-check method, yield cleaning technicians are able to determine the proper initial settings after manually examining only 10 fields from each farm annually. After finding the proper settings for the farm, technicians are able to use low-level programming to automatically clean the harvest data from the remaining fields. This saves farmers a lot of time working with data and still provides the high level of accuracy needed for yield estimation.