Adverse conditions for growers have continued through the last two weeks in June. In eastern New York, many of the dairy farms are still making final attempts at planting short day silage corn to supplement their inventories for the coming fall and winter months. Luckily for most dairy farms, the last two years have produced bumper crops that have padded feed inventories, preparing dairymen and women for the potentially poor yields that may ensue after this growing season.

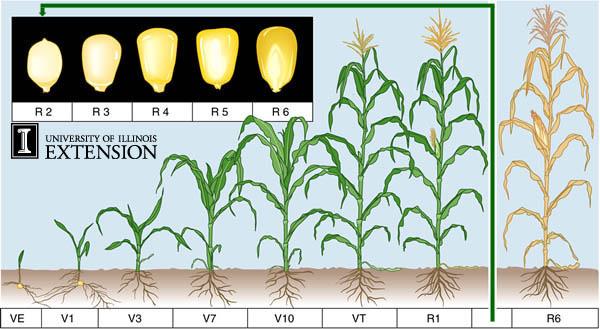

I have been kept busy in the fields scouting, as their is corn staging from V8 stage to corn that is not planted yet. In the V8 corn, we are beginning to look for fungal diseases and pest pressures, while also scouting for any emergency last-minute weed spraying that needs to be done before the canopy closes between the rows. Moving down the staging chart, much of the V6 corn is being side-dressed with Urea before stem elongation begins to take place. Bindweed is continuing to pop up everywhere, and farmers are being notified almost immediately when this trouble weed is found in the field. In the fields that are pre-plant to V6, we are keeping our eyes open for any seedlings coming in, and determining whether or not they have potential to cause issues in the growing process.

I did not realize coming into my internship that my Class B commercial license would come in handy as much as it has. With spurts of weather being few and far between, when it is time to roll the fertilizer and spray has to be applied- in a hurry. This is where I recently had my first opportunity to both sidedress corn and topdress hay ground. I have covered almost 700 acres on my own at this point in my brand new Vector 300 dry fertilizer spreader truck.

Though intimidating at first, the truck took little time for me to get used to. I am using the Raven GPS software package for all my different jobs and applications that I have been completing. In the software, I have learned of the number of different variables that need to be taken into account when applying fertilizer. There are five important aspects of the spreader and software that need to be monitored before starting a job. The first is the rate in pounds per acre that will be applied to the field. In order to achieve this rate, you need to have the right density of the material entered into the software, as this will make a difference in how fast the product comes out of the spreader. Another variable is spinner speed, which controls your working width. The last two variables are the door height on the spreader box and the table setting where the fertilizer falls on to the spinners.

I am learning there is a lot that goes into spreading fertilizer, much more than I previously thought. If any of these variables are out of sync, the rate will be off, which may lead to an unhappy farmer. Each job is a new challenge covering new terrain, and it is truly joy!