Bill Cox, School of Integrative Plant Science, Soil and Crop Sciences Section, Cornell University

Correct soybean planting depth is considered essential for maximum soybean yields. Too shallow a seeding depth (<1.0 inch) may result in poor early stand establishment. Soybean must imibibe half of its weight in water before it germinates. Tilled soils may dry out in the top inch after planting, resulting in the initiation of the emergence process but not completion. Consequently, poor stand establishment can occur at a shallow planting depth because of seed desiccation under extended dry periods after planting. On the other hand, planting deeper than 2.0 inches may also result in poor stand establishment. The soybean hypocotyl, the plant part that breaks through the soil surface during soybean emergence, is somewhat fragile. Heavy rains after planting may result in soil crusting, resulting in hypocotyl damage and unsuccessful emergence, especially for deep-planted soybeans struggling to break through a thick soil crust.

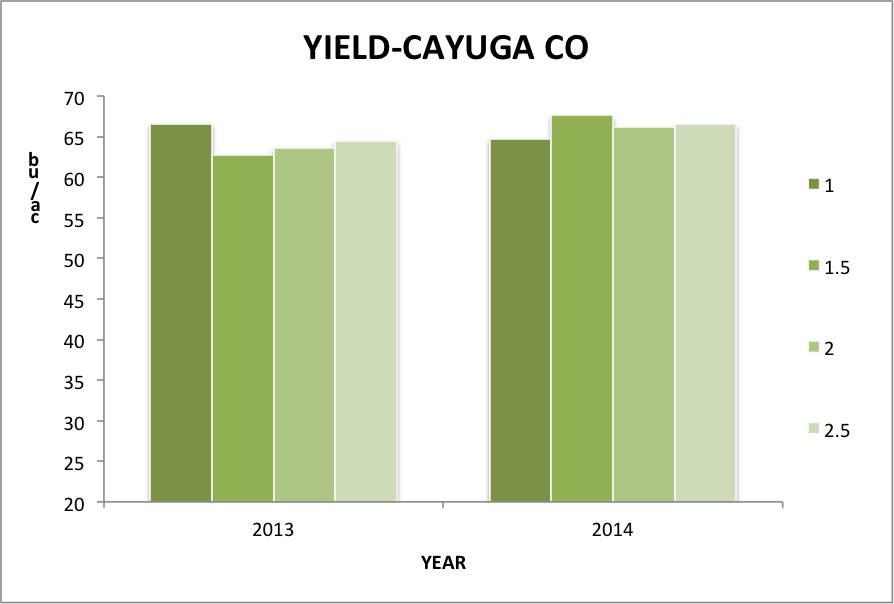

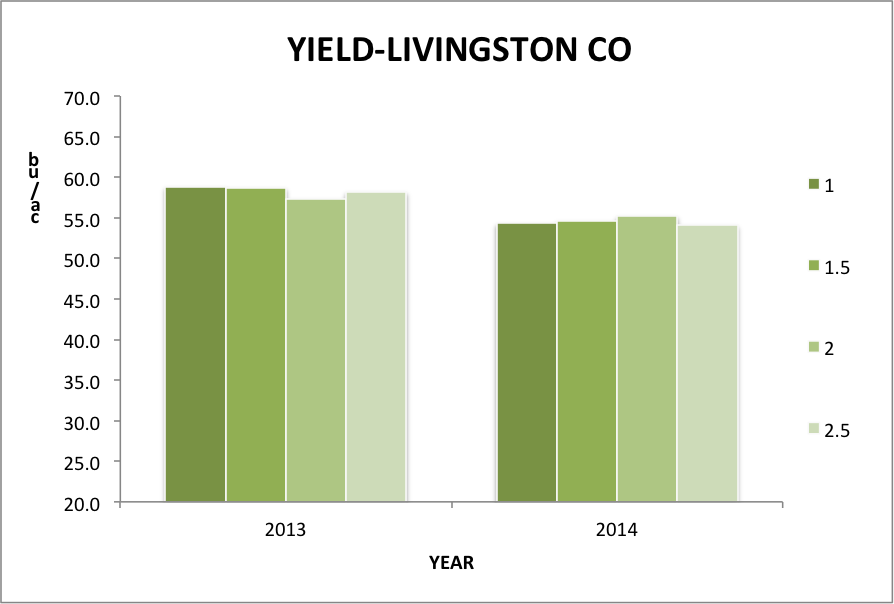

We conducted field-scale (5 to 10 acre) studies in 2013 and 2014 with growers in Cayuga, Livingston, and Tompkins County to evaluate early plant populations and yield of soybeans planted at 1.0, 1.5, 2.0, and 2.5 inch depths. Group II varieties were used at all sites but varieties differed as did planting dates (May 8 and May 24 at Cayuga Co.; May 27 and June 6 at Livingston Co.; and May 18 and June 2 at Tompkins Co. in 2013 and 2014, respectively), and seeding rates (~140,000 seeds/acre at Cayuga and Livingston Co. and ~175,000 seeds/acre at Tompkins Co.). Silt loam soils predominated at the Cayuga Co. site, clay loam soils at the Livingston Co. site, and gravelly loam soils at the Tompkins Co. The Cayuga Co. site (30-inch rows) was no-tilled, and the Livingston and Tompkins Co. sites (15-inch rows) were chisel-tilled. Corn was the preceding crop at all sites.

Negative linear responses of plant populations to seeding depths were observed at Livingston and Tompkins Co. sites in both years, indicating a decrease in early plant populations as seeding depth increased from 1.0 to 2.5 inches (Table 1). In contrast, seeding depth did not affect early soybean plant populations at the Cayuga Co. site in 2013, and showed a positive quadratic response to seeding depth in 2014 (no significant increase in early plant populations beyond the 1.5 inch depth). It is not clear if soil type (silt loam soil), row spacing (30-inch rows), land preparation (no-till), or planting date (earliest planting date among three locations in both years) influenced the different response at the Cayuga Co. site, or if the response was unique to this particular farm. Visual observation during plant population estimates in 2014, however, indicated poor penetration of the planter unit in one of the rows at the 1.0 inch depth, resulting in low plant populations in that row, suggesting that the response was unique to this farm in Cayuga Co.

Early plant populations at all sites in both years exceeded ~114,000 plants/acre, except at the 2.5 inch depth at Livingston Co. in 2013, the threshold below which soybeans yields decreased in previous studies in NY (Cox and Atkins, What’s Cropping Up, Vol.21, No.2, p. 5-6). Consequently, it was not clear until harvest if plant population decreases with deeper seeding depths were of sufficient magnitude to result in yield differences. Soybean yields at the Cayuga Co. site showed a positive quadratic response to seeding depth with maximum yield occurring at the 1.0 depth in 2013, despite no differences in early plant populations (Fig.1). In 2014, the 1.5 inch depth yielded the greatest (least at the 1.0 depth with early plant populations of ~111,000 plants/acre) , similar to the early plant population response (Fig.1). Despite negative linear responses of early plant populations to seeding depth at the Livingston Co. site, yields did not respond to seeding depth in either year of the study (Fig.2). Evidently, early plant populations of ~112,000 plants/acre in 2013 was sufficient to attain maximum soybean yield at this site. Soybean yields showed a positive quadratic response to seeding depth at the Tompkins C. site in 2013 with maximum yields occurring at the 1.5 inch depth, but yield did not respond to seeding depth in 2014 (Fig.3). It is not clear why the early plant population response to seeding depth was consistent across years, but the yield response to seeding depth was inconsistent across years at this location.

Conclusion

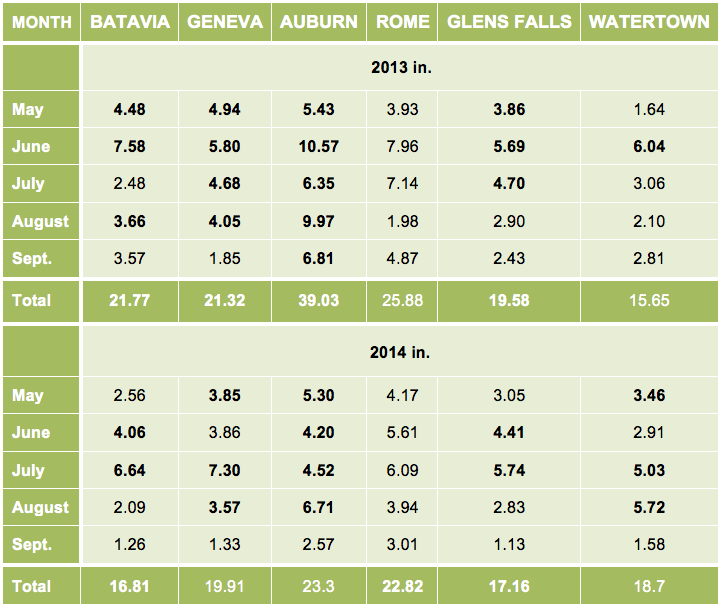

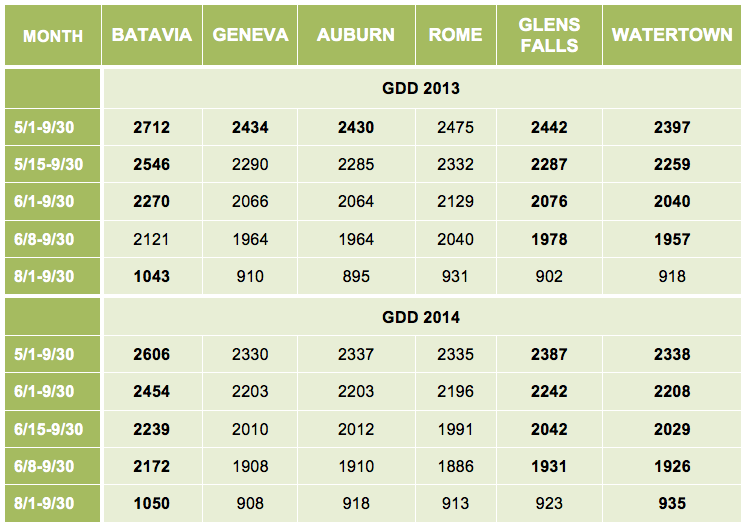

Late May and early June conditions were generally wet and warm at all locations in both years so weather conditions were not conducive to drying of the seed at the 1.0 inch seeding depth, nor soil crust development and subsequent hypocotyl damage to deep-planted soybeans. Consequently, soil and weather conditions were close to ideal for soybean emergence. Nevertheless, deeper seeding depths (2.0 to 2.5 inch range) consistently decreased early plant populations at two sites in both years, indicating that deeper planted soybeans, especially beyond the 1.5 inch depth, can result in poorer stand establishment even under ideal emergence conditions. At the third site, however, where soybeans were no-tilled in 30-inch rows, seeding depth had minimum effect on early plant populations, except at the 1.0 inch depth in 2014, when one planter unit had trouble penetrating the soil. It is not clear if 30-inch row spacing (~8 seeds/foot of row combining to break through the soil compared to 4-5 seeds/foot of row in 15-inch rows) allowed for better emergence from the deeper seeding depths at this location.

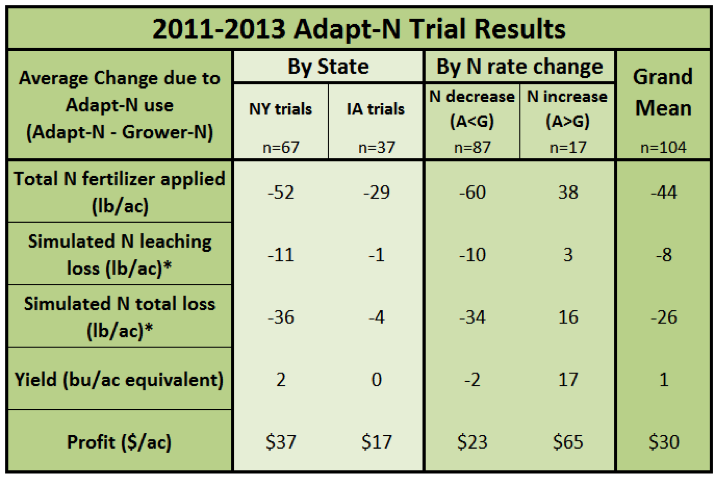

Yield did not respond to seeding depth in 3 site/years and showed quadratic responses in 3 site/years. Yield differences, however, were generally small at responsive sites with only 4.5 to 6.0% differences between the highest and lowest yields at the 30-inch row, no-tilled site, and 7.0% at the gravelly loam site. Despite the somewhat muted yield responses in this study, in part because of ideal conditions for emergence (>72% for all seeding depths at all sites in both years), soybean growers should be mindful that the 1.0 inch seeding depth can be too shallow in some instances (Cayuga Co. in 2014) and the 2.5 inch seeding depth can be too deep in some instances (Tompkins Co. site in 2013). The 1.5 inch seeding depth generally resulted in excellent early stand establishment (>85% emergence for all site/years except for 77% at Tompkins Co. site in 2013) and maximum yield in two of the three instances where yields responded to seeding depth. Growers should probably strive to be ~1.5-2.0 inch seeding depth range to avoid potential desiccation of the seed at depths < 1.5 inch and potential soil crusting problems at depths >2.0 inches.