Kristen Loria1, Allan Pinto Padilla2, Jake Allen1, Christopher Pelzer1, Sandra Wayman1, Miguel I. Gómez2, Matthew Ryan1

1School of Integrative Plant Science, 2Charles H. Dyson School of Applied Economics and Management, Cornell University, Ithaca, NY 14853.

About the Cornell Organic Cropping Systems Experiment

The Cornell Organic Cropping Systems (OCS) experiment was established in 2005 at the Musgrave Research Farm in Aurora, New York to serve as a living laboratory for organic field crop management systems and provide practical insights to farmers. This ongoing long-term experiment compares four management systems along a dual spectrum of external inputs and soil disturbance over a multi-year crop rotation. An advisory board consisting of a dedicated group of organic farmers provides guidance on management decisions. The four systems are compared in terms of several sustainability indicators including yield, profitability, soil health and greenhouse gas emissions.

Both external input and soil disturbance gradients of the four treatment systems range from an extensive approach (low input) aimed at maximizing profitability by reducing costs via efficient resource use, to an intensive approach (high input), aimed at maximizing profitability by maximizing yield. Risk associated with low input management includes reduced crop production from inadequate soil fertility or weed competition, which can lead to decreased returns despite low input costs. Risk associated with high input management include diminishing returns where productivity increases are insufficient to justify additional cost.

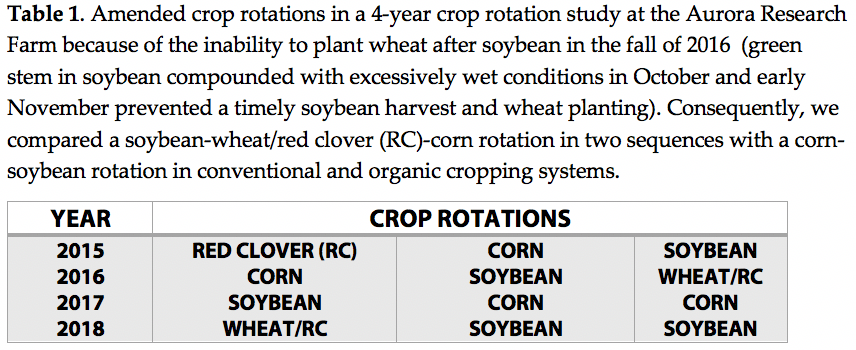

The four management systems of OCS are: 1) High Fertility (HF), 2) Low Fertility (LF), 3) Enhanced Weed Management (EWM), and 4) Reduced Tillage (RT). In 2018, the crop rotation was modified from a three-year rotation to a four-year rotation based on advisor input.: This article includes an economic analysis of the complete four-year crop rotation cycle from 2018-2021, which consisted of: 1) triticale / red clover, 2) corn / interseeded cover crop mix, 3) summer annual forage mix / cereal rye cover crop, 4) soybean (Figure 1).

Figure 1. Four-year crop rotation for the OCS phase 2018-2021.

Looking back: key takeaways from past OCS cycles

Caldwell et al. (2014) compared the yields and the profitability during and after the initial phase of organic transition in OCS following two three-year rotation cycles (corn-soybean-winter spelt/red clover) from 2005-2010. The first three years were considered as transitional production years in which crops could not be sold as certified organic, while crops produced from 2008 to 2010 could be sold as such. They used flexible interactive crop budgets to calculate relative net returns based on crop yields, tillage, weed management and fertility practices and, after the three-year transition period, compared relative net returns of organic production with concurrent organic price premiums to Cayuga County yield averages with conventional crop production inputs and prices. With a 30% organic price premium, the relative net return of organic production in all systems except RT was positive. The RT system was excluded from most analyses due to major challenges with experimental ridge-till practices resulting in decreased crop competitiveness. For both corn and soybean phases averaged across entry points, relative net return in the HF system was significantly lower than LF or EWM, due to higher input costs without corresponding higher yields in the HF system. For the spelt phase averaged across entry points, relative net return was higher in HF than LF and EWM (though not significantly so), with increased input cost in the HF system corresponding with a yield increase. The HF system led to higher weed biomass over time than the EWM and LF systems.

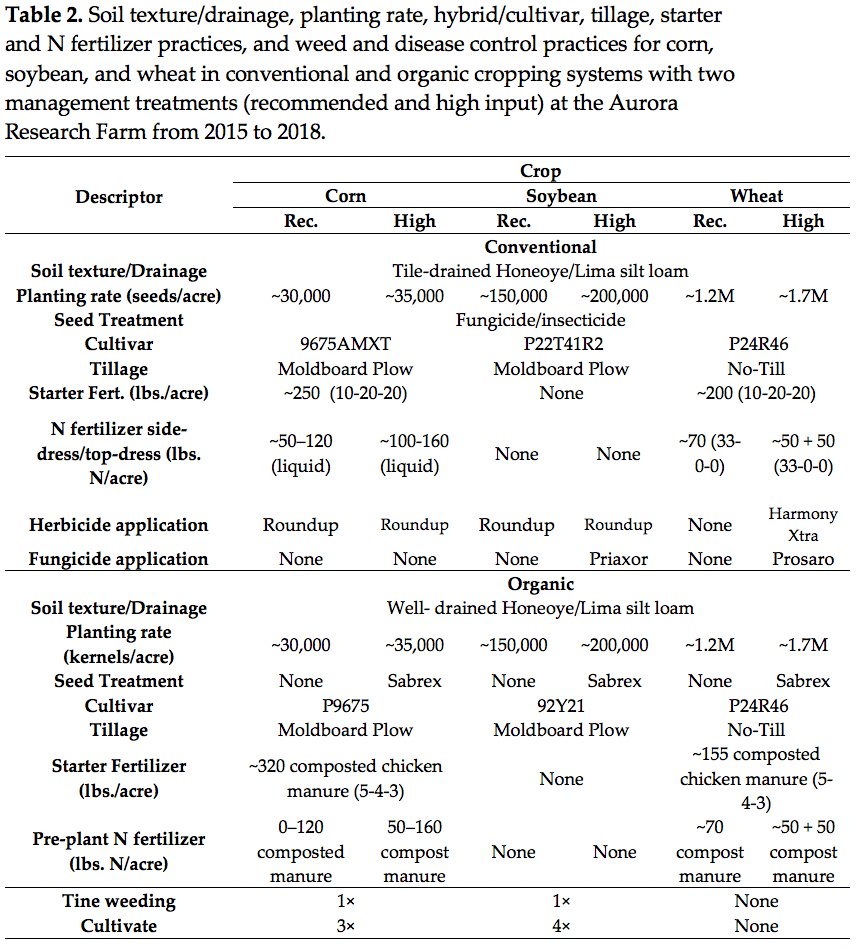

Trial design and system differences

The Cornell Organic Cropping Systems experiment uses a split-plot randomized complete block design with four blocks. The main plot treatments are the four management systems, whereas subplot treatments are two crop rotation entry points (A and B) . Entry points A and B represent different phases of the crop rotation. For example, in 2018 entry point A was planted to triticale while entry point B was planted to soybean.

Treatment systems are arranged along a fertility gradient as well as a soil disturbance gradient (Figure 3). For triticale, summer forage, and corn, the HF system had a 50% higher fertilization rate than RT and EWM. LF received fertilizer rates 50% lower than RT and EWM on the same crops. Intermediate fertilizer rates were applied to both EWM and RT. With respect to soil disturbance, EWM received additional weed management operations in several crops, while RT and LF incorporated an organic no-till soybean phase. Overall number of primary tillage events was not substantially different between systems, though mechanical cultivation was reduced in the soybean phase for RT and LF.

Figure 2. Contrasting management approaches in four systems.

Crop yields across management systems

No matter the management system, crop yield is a key component of profitability. Yields across all four years of the cycle comprising five harvested crops are summarized below. Ryelage was only harvested in EWM and HF systems as the cereal rye cover crop was rolled-crimped for no-till soybean in LF and RT systems. Triticale was grown as a grain crop in EWM and HF and taken for forage in the LF and RT systems. Organic no-till practices were implemented in RT and LF systems only, with soybean planted into tilled soil in HF and EWM. In entry point A soybean yields were comparable across systems, but in entry point B organic no-till soybean yields were nearly half of cultivated yields, likely due to dry conditions in the soybean phase in 2018.

Table 1. Mean yields for all harvested crops across four management systems and crop rotation entry point from 2018-2021. Within an entry point, systems sharing a letter were not significantly different (p < 0.05). Means were not compared between entry points. Triticale in RT and LF systems was harvested as forage (lbs DM/ac) while in HF and EWM it was harvested as grain (lbs/ac). Means were not compared.

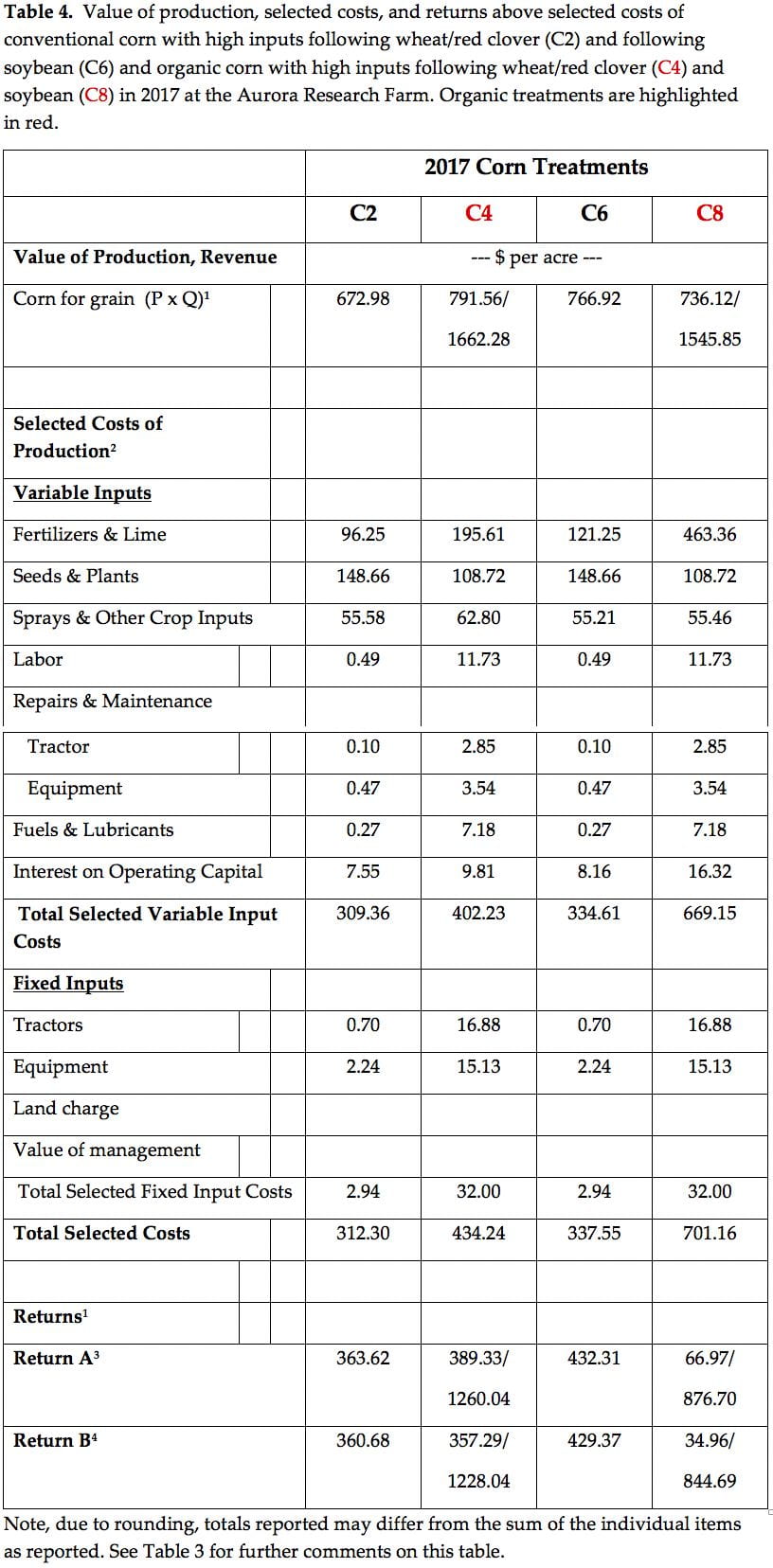

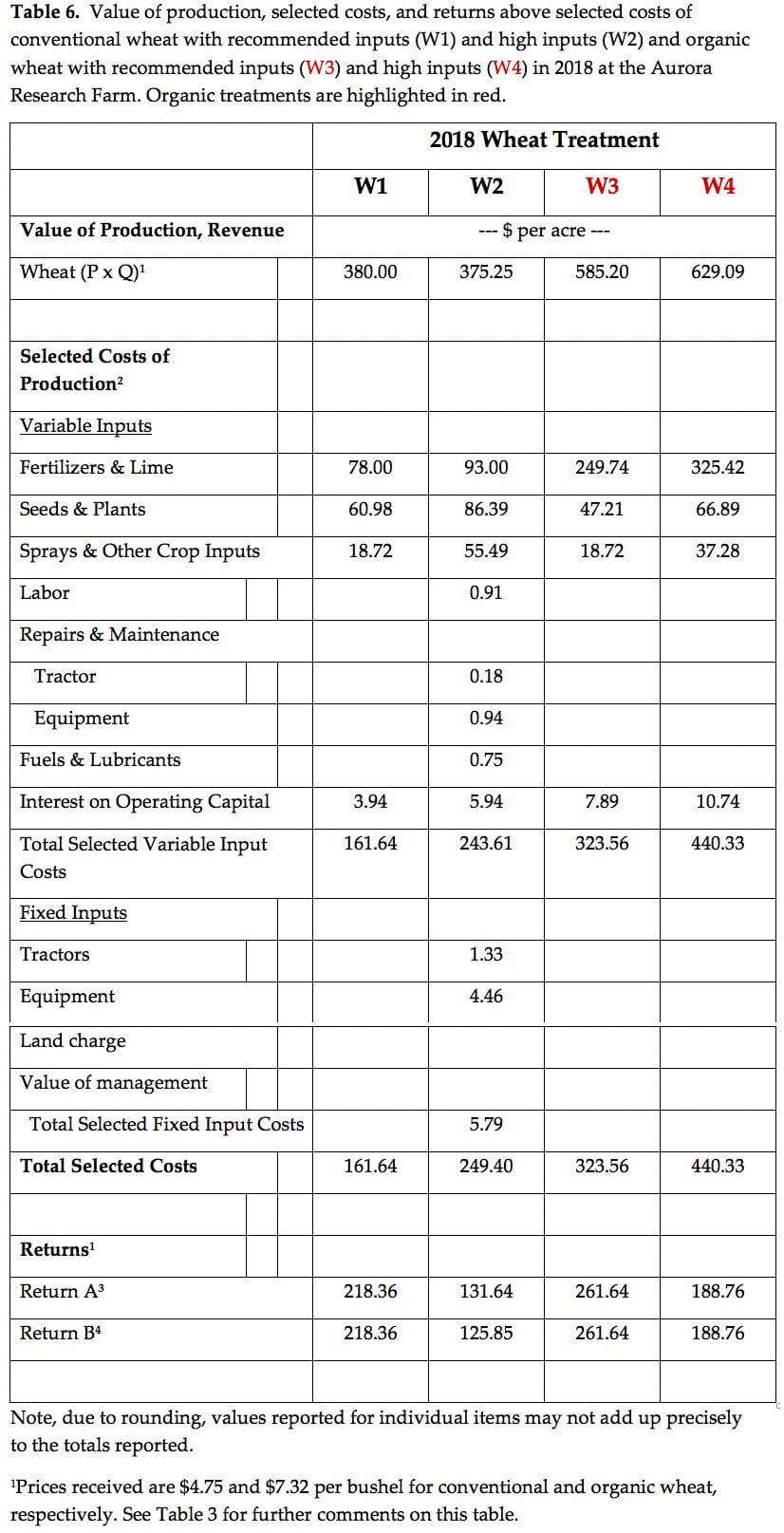

Net return of management systems

Net return subtracts total variable costs (TVC) of production (inputs + labor + equipment-associated costs) from gross income (crop yield x price). Prices for corn and soybean were obtained from the USDA organic grain report (USDA National Organic Grain and Feedstuffs Report, February 4, 2022). As commodity price references for triticale grain, cereal rye forage and summer annual forage were unavailable, prices were based those typically fetched for organic forage in NY (MH Martens and P Martens, personal communications, 2022). All operation-related costs were taken from Pennsylvania’s 2022 Custom Machinery Rates (USDA NASS 2023). To correct the absence of an inflation adjustment, crop prices and input costs used in this study were converted to real values using the U.S. Consumer Price Index (CPI), with 2016 as the reference year.

All values are denominated in U.S. dollars and represent the average annual revenue, production costs, and net return over four years. In the case of crop rotation entry point A, the LF cropping system exhibited the lowest Total Variable Cost (TVC). Conversely, the HF system had the highest TVC, which despite higher grain and forage yields, resulted in lower net return than LF, EWM and RT systems (Figure 4).

Overall, across four years of the crop rotation and in both crop rotation entry points (i.e., temporal replications of the trial) the EWM system maximized net return via intermediate fertility rates and relatively high yields, though the HF system yielded higher in both entry points Net return for RT and LF systems was more variable between crops and entry points, possibly indicating higher weather-related risk associated with those system approaches, i.e. reliance on cover crops for fertility in LF, and use of organic no-till management for LF and RT (Figure 4).

Figure 4. Comparison of net return and components across four systems in entry point A.

In entry point A, LF demonstrated higher net return than both HF and RT despite lower yields due to reduced input costs. Net return in RT narrowly surpassed HF due to lower input costs as well. In entry point B, LF ranked lowest in net return due to low grain yields across the rotation. HF ranked second and RT ranked third, with RT characterized by intermediate to low yields with intermediate input costs.

Figure 5: Comparison of net return and components across four systems in entry point B.

When net return of each management system is summarized by entry point, high variability in profitability was observed across entry points, largely due to yield differences between growing seasons of the same crop. Because management was nearly identical for each crop within each system across entry points, temporal variation in net return can be attributed to yield response from seasonal environmental or climatic factors either directly or in interaction with management. This highlights the complexity of systems experiments given year-to-year variation (Figure 6).

Figure 6: Net return comparison of all four cropping systems and two entry points.

Conclusions

Differences in yield and subsequent net return between systems varied significantly across entry points, making it difficult to draw conclusions on the most profitable system overall. However, the HF system had the lowest net return across entry points, indicating that input levels were likely higher than optimum and yield gains to justify increased inputs were not realized. EWM had the highest net return across entry points, indicating that intermediate levels of fertility combined with additional cultivation passes in the row crop phases and full tillage soybean production “paid off” as a management strategy, with increased labor or fuel costs outweighed by increased yields. Of course, this assumes availability of labor required which may be out of reach for some farms, and can be challenged by finite weather-related windows conducive to field operations.

Variability in net return between entry points was particularly high for the LF and RT systems, largely driven by yield variation in the soybean phase between temporal replications. For entry point B, intermediate corn yields and low organic no-till soybean yields drove low profitability in LF, while relatively high corn yield in RT partially made up for low organic no-till soybean yield. This variation in soybean yield highlights a challenge with an organic no-till management approach that dry conditions can reduce yields to a greater extent compared to a tillage-based approach. However, in an extremely wet year where adequate weed control was not possible, no-till management may pay off.

By accounting for system profitability only, this article does not consider other tradeoffs between systems such as soil health outcomes or greenhouse gas emissions from contrasting management, additional sustainability metrics to evaluate organic production system success.

References

Caldwell, B; Mohler, CL; Ketterings, QM; and DiTommaso, A. (2014). Yields and profitability during and after transition in organic grain cropping systems. Agronomy Journal, 106(3):871–880.

Gianforte, L personal communication. 2022.

Jernigan, A. B., Wickings, K., Mohler, C. L., Caldwell, B. A., Pelzer, C. J., Wayman, S., and Ryan, M. R. (2020). Legacy effects of contrasting organic grain cropping systems on soil health indicators, soil invertebrates, weeds, and crop yield. Agricultural Systems, 177:102719.

USDA National Organic Grain and Feedstuffs Report, February 4 2022. Agricultural Marketing Service.

Martens, MH personal communication. 2022.

Martens, P personal communication. 2022.

Pennsylvania’s 2022 Machinery Custom Rates. USDA NASS.

For more results from the Cornell Organic Systems Experiment visit the Sustainable Cropping Systems Lab website.