Digital Dermatitis, or Hairy Heel Wart, as most dairy farmers know it, is a painful experience for the cow, and a frustrating and costly lameness issue for the farmer. The case study I’ll share in this article was from a participating farm in our NY Farm Viability Institute grant project “Focus on Farm Management: Areas of Excellence and Opportunity with Calves, Transition Cows and Cow Comfort”. Participating farms received assessments in these three areas, worked with their Cooperative Extension Dairy Specialist to come up with an action plan, implemented the plan, and then had their farms reassessed about a year later. A benchmark of all fifteen participating farms was created for each farm to compare to, as well as against their original assessment.

Cow Measurements

This case study farm knew that heel warts and lameness in general was an area on their farm that they wanted to focus on. Their first assessment of cow comfort included lameness scoring, as well as hock and knee injury and hygiene scoring in their high pen. Upon comparison to the benchmark of participating farms, the farm’s suspicions were confirmed that lameness was an area they needed to focus on; while almost 80% of their mature high group scored sound, almost 15% scored mildly lame and almost 6% scored severely lame. Benchmark numbers in contrast showed over 86% sound, 11% mildly lame and less than 3% severely lame. Hock injuries were also a concern, with mild hock injuries over double the benchmark average. Knee injuries were better than benchmark, with none found, but hygiene was also shown to be worse than the benchmark, with only over 30% of cows scoring slightly dirty compared to only 20% of the benchmark.

Facility Measurements

Along with cow measurements, management factors were also assessed on each farm. Stall sizing as well as stall hardness, bedding amount and cleanliness, and stocking density were evaluated and compared to benchmark. Bedding amount at first assessment was scarce, as the farm only bedded once per week, but stall base hardness and bedding cleanliness were both close to recommendations. The farm also noted their stocking density was almost 125% of stalls, but thankfully with lots of feed and water space, were achieving 23” of bunk space and 3.3” of water space per cow in that pen.

Forming the Action Plan

After talking through the first assessment results, the farm wanted to develop their action plan to focus on improving their numbers associated with lameness and injuries. The first area they decided to work on was bedding in the stalls – to save time, they had been bedding only once per week. They changed that two twice a week. As hygiene was a concern, they took a good look at stocking density and the number of cows in the pen and did some strategic movement of cows, as well as implementing a better scraping schedule. We also invited a third party to assist us in thinking “big picture” about how we can more fully impact lameness on this dairy.

A third set of eyes

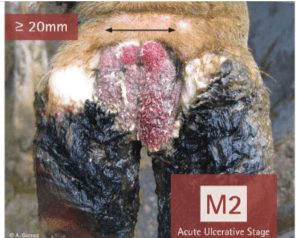

Inviting the third set of eyes turned out to be the key for this dairy. We met as a group to go over the goals for the herd and what we found in the assessment, and then walked the dairy in the same pathways as the herd walks them. Because heel warts were a significant concern, the outside eyes discussed common issues that occur on dairies that also struggle. Areas of uneven ground, standing water/manure slurry, and 90 degree turns with elevation change were all areas pointed out to be addressed. These things, along with areas that are slip hazards for cows, are all places for the skin on the back of the foot to get micro-tears and allow the DD pathogen to enter and infect the foot. Evening out areas of the flooring, adding rubber strategically, and more grooving to prevent slipping were recommended to the dairy.

Footbath Changes

A big change for the dairy was also implementing a better footbath strategy. The footbath was in a strategic location – easy to fill and easy to clean, and able to be bypasses if necessary. Footbath design was also correct – 12 feet long and narrow, with no option for cows to go around or step over. They were achieving the correct number of dunks per foot, but were concerned with cost of Copper sulfate and total cost of baths. Right off the bat, we calculated the correct amount of copper for the bath, and found their percent solution was less than adequate. Secondly, we implemented a soap bath. Remember, hygiene scores were less than ideal. In dealing with heel wart, our treatment must get to the skin and if manure is caked on, the treatment cannot reach the skin. The farm decided to implement the soap bath protocol 2-3 days before a treatment bath, and focus on cleaning feet with the hose in the parlor for those that needed extra attention.

The Results

About nine months after making changes, the farm received their second assessment. The results? The cases of severe lameness disappeared, and the foot trimmer had far less heel wart cases to treat. In addition, attention to the stalls showed that severe hock injuries also dramatically increased, and hygiene scores improved to benchmark averages. The farm is now controlling stocking rate to 115% and focusing on keeping the footbath protocol up to snuff, as well as keeping a focus on hygiene. The keys to get the farm to make changes? In their words, “Having an outside person to point out areas to improve, having an external motivation”.

If you’d like to focus on foot health, feel free to reach out. I’d be glad to be your third set of eyes!