So, you spot a used pressure canner at a thrift store. Given the average price of a new pressure canner [around $200.00], that $25.00 price tag looks pretty good, but is the canner safe to use? What should you look for before using an older pressure canner? Extension employee Leslie Swartz recently posed that question to the Master Food Preserver group. Leslie had been gifted with a used Presto pressure canner and asked the group to evaluate it for safety.

First Things First: When do I use a Pressure Canner?

A boiling water bath canner is fine for processing high acid foods like jams and pickles because molds, yeast, and enzymes are destroyed at temperatures below 212°F [the boiling point]. However, botulism spores can survive a boiling water bath, creeping inside the sealed jars of foods. Pressure canners use—well—pressure to heat the inside of the canner to 240 degrees. Water inside the canner is transformed into steam, which replaces the air in the canner, forcing the air out of jars and preventing bacteria from coming in. [The Cooperative Extension offers hands-on classes in how to use a pressure canner. See the Extension’s Events schedule.]

The Parts

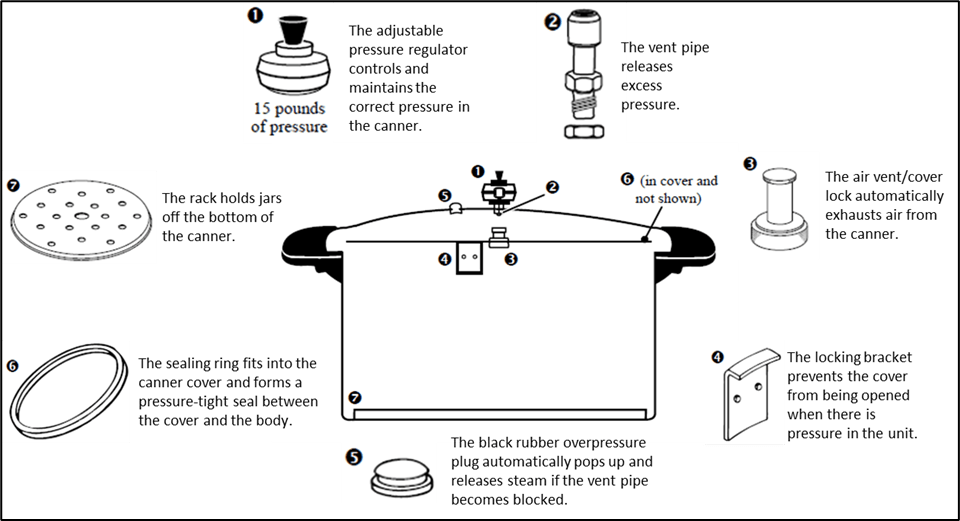

The first thing the group asked was to see the canner’s user manual. We found the model number stamped into the side of the body and found the user manual online. The diagram below is an excerpt from How to Use and Care for Your Presto® Pressure Canner. Considering the critical functions of the various parts during the canning process, the group checked each part to see that it was in usable and working condition.

First Impressions

One MFP suggested checking the bottom of the canner body to see if it was perfectly flat because a warped canner bottom will prevent the canner from heating evenly. Our canner did not rock on a flat surface; its bottom was flat.

Someone suggested checking both the canner and the cover to ensure both were perfectly round. Since the top fit properly—snuggly and evenly—the group approved it. The group found no dents in the cover or canner body.

Pitting, a kind of corrosion that leads to pinholes in metal, can be caused by any number of things, including salt or vinegar, scratches, or storing the canner in a damp location. Pitting can lead to weak spots in the canner, but our canner was in good shape.

Air vent/Cover Lock and Sealing Ring

A black rubber gasket, called a sealing ring, fits along the inside bottom of the cover. The sealing ring helps form a tight seal between the cover and the body during canning. Like any rubber component, the sealing ring should be replaced if the rubber becomes hard, cracked, or inflexible. Our canner came with a new sealing ring.

Once pressure builds inside the canner, the air vent/cover lock pops up, locking the cover onto the canner body and automatically exhausting air from the canner. The air vent/cover lock must move freely within its socket, which ours did.

Vent Pipe

The group noted the metal stem poking out of the cover. That stem is the vent pipe through which steam escapes the canner throughout the canning process. Once the canner is filled and locked, it is heated until a steady stream of steam flows through the open vent pipe. After ten minutes, all the air from the canner is expelled, and a pressure regulator [See below.] is placed atop the vent pipe. The pressure regulator maintains the desired amount of pressure within the canner—typically, 5, 10, or 15 pounds—by allowing any excess steam to sneak out the vent pipe.

Knowing how the vent pipe is used, it is understandable that the vent pipe be free of obstacles, which ours was. Incidentally, if the vent pipe becomes blocked and cannot release pressure, the black rubber overpressure plug will automatically pop out and release steam. Like the sealing ring, this rubber plug should be flexible and free of cracks; ours was.

Pressure Regulator

Different pressure canners use different types of pressure regulators. Our model uses a “weighted-gauge” pressure regulator consisting of a five-pound body, shown in the photo below, and two five-pound weighted rings. The pressure can be adjusted to accommodate 10 and 15 pounds of pressure by adding the weighted rings. Leslie ended up buying a new weighted gauge for her canner because the two rings were missing.

Dial Gauge

The last step before testing the canner was to install the dial gauge in the hole in the top center of the cover. The gauge has a threaded post that is secured on the underside of the cover with a nut. [The previous owner had purchased a new gauge, which the Cooperative Extension tested and approved. See Resources for how to have your gauge tested.]

We discovered at this point that the cover and body were mismatched. According to the Presto representative—and the parts diagram—our model did not support a cover with a dial gauge, but our

cover clearly needed one. Since we had no way of knowing the model number for the cover, we could not search for a user manual or list of replacement parts for it.

Also, as seen in the photo above, the replacement dial gauge came with a black rubber gasket, a one-piece unit designed to seal on both sides of the cover. Try as we might, we could not thread that gasket through the center hole in the cover to install it.

On the Presto web site, the only replacement part NOT listed for purchase for our model was the dial gauge—we had hoped to view the part to see if that gasket was necessary. We found a video demonstrating how to change the dial gauge on a similar canner, and that gauge did not use a gasket.

Further [extensive!] research revealed that our small black rubber gasket was, in fact, some kind of adapter that we didn’t need. Your pressure canner might need one of these gaskets, so again, refer to your canner’s user manual. Our dial gauge fit nicely, secured underneath by a nut tightened with an adjustable wrench.

Testing the Canner

Even after satisfactorily evaluating of all the parts and installing the dial gauge, we were all still a tad leery about using the canner. Our biggest concern was that the cover would not seal correctly; however, in that case, we knew that steam would leak from between the cover and the body—we would see the steam leak. [We did not.]

If the cover did not latch properly, the cover might lift off the body; however, we would know that the cover had latched properly when the air vent/cover lock popped up. [It did.]

Finally, we knew that the vent pipe and overpressure plug were in working condition and would engage to prevent the canner from blowing apart. [They did.] We canned several jars of chicken broth following instructions from the National Center for Home Food Preservation while carefully monitoring the canner. We experienced no errors or flaws.

Conclusion

Many more hours of research and discussion went into the preparation of this blog than what the final product comprises, but we needed to err on the side of safety, and so must you. While all those hours may seem like overkill, the fact that the cover and body were mismatched was new territory for most of us and of great concern. We were justifiably worried about the cover not sealing properly on the mismatched body and what could happen. We sometimes joke about pressure canners exploding, and it does happen, but mainly due to blocked valves or vents. We had thoroughly checked and/or replaced all parts of our canner and decided that it was safe to use, which it was.

So, will you use a used pressure canner? If, after going through all the steps we went through, you are still not confident in the canner’s usability, please contact the Local Foods Program Leader for assistance. (See Resources below.) The Master Food Preserver group would love to help! Keep in mind that, along with facilitating the continued use of a piece of equipment that will last for years if properly cared for, our efforts kept yet one more item out of the landfill!

Resources

Where can I buy Replacement Parts?

Look for replacement parts for pressure canners in hardware stores, on Amazon, etc. Be sure to first check with the canner’s user manual or with the manufacturer so that you purchase replacement parts specific to your canner. These parts were purchased for our canner:

- Sealing ring [around $12]

- Pressure regulator [around $12]

- Dial gauge [about $20]

Local Help

Contact Cornell Cooperative Extension to have your pressure canner dial gauge tested free of charge:

Flip Filippi

Local Foods Program Leader & Harvest Kitchen Manager

mpf65@cornell.edu

315-379-9192 ext. 229

Where can I Find More Information?

Cornell Cooperative Extension of St. Lawrence County periodically offers classes on many different food preservation techniques including pressure canning. Sign up for the weekly e-news to learn about newly scheduled classes here.

Cornell Cooperative Extension of Saratoga County has food preservation resources on their website that includes video presentations and fact sheets.

The National Center for Home Food Preservation provides current research-based recommendations for most methods of home food preservation, including several articles about pressure canners.

Kathryn Farr has been growing and preserving vegetables and fruit for many years. She completed the Extension’s Master Food Preserver Volunteer training in 2022 and was recently certified as a Cornell Cooperative Extension Master Food Preserver.