Ongoing and recently completed projects include:

Supercritical Fluid Extrusion (SCFX)

Supercritical fluid and extrusion processes are two very distinctly separate unit operations in practice on commercial scales around the world and we have been involved in conducting research in both these areas for some time. Our observations regarding the commonality of high pressure between these two processes has led us to develop a new hybrid unit operation termed Supercritical Fluid Extrusion (SCFX), combining the unique advantages of both to create a new generation of novel extruded products. The process offers the following advantages:

- Low-temperature (<1000C) and low-shear expanded product, not available via traditional cooking extrusion

- Heat sensitive ingredients included in formulations, in-barrel addition of flavorings and colorants

- Variable number and size of cells for texture control

- Dual texture, porous interior with smooth external surface

- Flavor and bioactives encapsulation on the interior surface of cellular structure

- Reactive extrusion via pH control through in barrel formation of carbonic acid

- Low barrel wear and tear

- Products made: Breakfast cereals, snack foods, pasta, chocolate and confectionary, coffee, leavened of dough & bread, milk protein and whey protein crisps, among others.

- Paraman, I., Wagner, M.E. and Rizvi, S. S. H. 2012. Micronutrient and protein-fortified whole grain puffed rice made by supercritical fluid extrusion. J. Agric. Food Chem. 60: 11188−11194.

- Khanitta R., Wagner, M. E. and Rizvi, S. S. H. 2011. Properties of yeast free bread produced by supercritical fluid extrusion (SCFX) and vacuum baking. Innovat Food Sci. Emerg Technol 12: 542–550.

- Ayoub, A. and Rizvi, S. S. H. 2011. Reactive supercritical fluid extrusion for development of moisture resistant starch-based foams. J. Appl. Poly. Sci. 120: 2242.

- Manoi, K. and Rizvi, S.S.H. 2009. Physicochemical changes in whey protein concentrate texturized by reactive supercritical fluid extrusion. J. Food Eng, 95: 627-635.

- Alavi, S.H., Rizvi, S.S.H. and Harriott, P. 2003. Process dynamics of starch-based microcellular foams produced by supercritical extrusion I: model development. Food Res. Int’l. 36:309 – 319.

- Alavi, S.H., Rizvi, S.S.H. and Harriott, P. 2003. Process dynamics of starch-based microcellular foams produced by supercritical fluid extrusion II: numerical simulation and experimental evaluation. Food Res. Int’l. 36:321 – 330.

Liposomal Assemblies and Microencapsulation

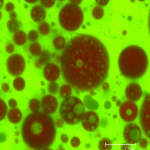

Liposomes are intelligently designed nanoscale vesicles that use a phospholipid bilayer as a protective barrier, similar to the natural storage, transport and secretory vesicles generated by living cells. Because of their amphiphilic nature, they are able to simultaneously encapsulate both hydrophilic and hydrophobic compounds, giving flexibility to deliver many types of cargo. They are particularly ideal for site specific delivery of bioactives to the body, due to their similarity to natural cells. Used as a biocompatible carrier system, liposomes can also promote the physiological activity and safety of the entrapped components. They are already being used in the pharmaceutical industry, but their reliance on the use of organic solvents and lack of control of particle formation limits their application in food and nutrition systems.

Liposomes are intelligently designed nanoscale vesicles that use a phospholipid bilayer as a protective barrier, similar to the natural storage, transport and secretory vesicles generated by living cells. Because of their amphiphilic nature, they are able to simultaneously encapsulate both hydrophilic and hydrophobic compounds, giving flexibility to deliver many types of cargo. They are particularly ideal for site specific delivery of bioactives to the body, due to their similarity to natural cells. Used as a biocompatible carrier system, liposomes can also promote the physiological activity and safety of the entrapped components. They are already being used in the pharmaceutical industry, but their reliance on the use of organic solvents and lack of control of particle formation limits their application in food and nutrition systems.

Taking advantage of high pressure, we have designed and developed a unique venturi-based system for the production of liposomes using supercritical carbon dioxide, a benign alternative to conventional solvents. In this system, nanoliposomes are produced using separate atomized streams for the cargo and carrier, and as such greater control of the final product size and lamellarity is achieved. Not only will this system allow for the safe production of these nanoliposomes, but also for the study of the fundamental aspects of nanoparticle formation. Current focus includes quantifying the effects of atomization mechanics on the formation of liposomes and development of models for the prediction of liposomal formation. Efficacy of the process is aimed to be demonstrated by the production of nanoliposomes containing selected bioactives and subsequent study of their storage stability and modeling of release kinetics.

Inactivation with Supercritical Fluids

Although the American food safety record is among the very best in the world, batches of ground beef, sprouts, peanut butter, pistachios, spinach, and even cookie dough have been implicated in serious outbreaks in recent years. We are currently evaluating the use of benign and environmentally friendly supercritical fluids like carbon dioxide, nitrous oxide, etc. as food safety decontamination processes of commercial utility. Although more sophisticated than many of the currently used commercial sterilization techniques, scf-based sterilization technology is ideally suited for hard-to-decontaminate, low-volume, high-value commodities like seed sprouts and nuts and selected meats. Scfs present unique advantages since they can easily penetrate cracks and crevices due to high diffusivity and low surface tension. It could reach uniformly at all sites within the seeds as well as on the seed surface, thereby targeting on-surface as well as internalized pathogens. We plan to investigate the effects of superimposed dense gas process variables (pressure, temperature, additives) and their mechanism of interactions for inactivation of microorganisms and enzymes in model and real food matrices and develop physically realistic models and correlations to accurately quantify the experimentally observed responses.

- Adi, M.S., Zoellner, C. and Rizvi, S.S.H. 2013. Current Intervention Strategies for the Microbial Safety of Sprouts. J. Food Protection, 76:2099–2123.

- Iftikhar, T., Wagner, M. E. and Rizvi, S. S. H. 2014. Enhanced inactivation of pectin methyl esterase in orange juice using modified supercritical carbon dioxide treatment. Int’l J. Food Sci. Technol, 49: 804–810

- Zoellner, C., Rizvi, S.S. H and Worobo, R. 2014. Decontamination of alfalfa sprout seeds contaminated with E. coli O157:H7 using supercritical carbon dioxide and peroxyacetic acid hurdle treatment. In review.

Engineering Properties of Food Biomaterials

Food systems encompass a wide range of multi-component, multi-phase, heterogeneous biological materials and the control and predictability of their behavior plays a major role in the design of processes for efficient manufacture of better quality products. Yet, despite numerous research investigations over the last several decades, our understanding of the role of various constituents in structure-property relationship of food remains largely empirical. Non-equilibrium processes like extrusion, drying, freezing, baking, etc. experiencing constant changes in energy and phases pose additional constraint on the time- and space-dependent prediction of their behavior during manufacturing and storage.

Moreover, the rules for non-equilibrium thermodynamics of inhomogeneous systems like foods are not well-established and also require a knowledge of rates of reaction of the constituents which often lead to instabilities and fluctuations. Engineering intuition, trial and error and rules of thumb are still used in design of many operations which often do not perform as expected. We have evaluated and continue to work on both the equilibrium and non-equilibrium processes and properties as they relate to the role of water in stability of foods. We have also conducted experimental measurements and developed correlations and models for viscosity, diffusion coefficients and phase equilibria of selected binary, ternary and multicomponent systems. Modeling multicomponent systems remains a challenge and depends on the parametric effects of the selected properties. Our focus has been on the diffusivities and viscosities of lipid-rich and supercritical carbon dioxide (sc-CO2)-rich phases and distribution of the components in the two phases. Though temperature and pressure dictate the solubility and distribution of components in the two phases, we are interested in using the density as a scaling factor in new correlations.

Moreover, the rules for non-equilibrium thermodynamics of inhomogeneous systems like foods are not well-established and also require a knowledge of rates of reaction of the constituents which often lead to instabilities and fluctuations. Engineering intuition, trial and error and rules of thumb are still used in design of many operations which often do not perform as expected. We have evaluated and continue to work on both the equilibrium and non-equilibrium processes and properties as they relate to the role of water in stability of foods. We have also conducted experimental measurements and developed correlations and models for viscosity, diffusion coefficients and phase equilibria of selected binary, ternary and multicomponent systems. Modeling multicomponent systems remains a challenge and depends on the parametric effects of the selected properties. Our focus has been on the diffusivities and viscosities of lipid-rich and supercritical carbon dioxide (sc-CO2)-rich phases and distribution of the components in the two phases. Though temperature and pressure dictate the solubility and distribution of components in the two phases, we are interested in using the density as a scaling factor in new correlations.

- Khanitta R., Wagner, M. E. and Rizvi, S. S. H. 2011. Properties of yeast free bread produced by supercritical fluid extrusion (SCFX) and vacuum baking. Innovat Food Sci. Emerg. Technol. 12: 542–550.

- Chen, K-H. J. and Rizvi, S.S.H. 2006. Measurement and prediction of solubilities and diffusion coefficients of carbon dioxide in starch-water mixtures at elevated pressures. J. Polymer Sci. Part B: Polymer Physics 44: 607-621.

- Hicsasmaz Z.and Rizvi S.S.H. 2005. Effect of size and shape on modulus of deformability. LWT – Food Sci. Technol.: 38:431-435

- Tuan, Dang Quoc, Zollweg, J. A., and Rizvi, S. S. H. 1999. Concentration dependence of the diffusion coefficient of lipids in supercritical carbon dioxide. Ind. & Eng. Chem. Res. 38: 2787-2793.

- Zou, M., Yu, Z.R., Rizvi, S.S.H. and Zollweg, J.A. 1999. Fluid-liquid equilibria of ternary systems of fatty acids and fatty acid esters in supercritical carbon dioxide. J. Supercrit. Fluids 3: 85-90.

Bioseparation Processes

Bioseparation steps often pose the greatest impediment to scale-up and commercialization of a process. Bioseparations using conventional techniques (distillation, absorption, solvent extraction, etc.) are often impractical because many biomaterials are of high molecular weight, have very low vapor pressure and are often unstable at elevated temperatures. The separation of multicomponent mixtures of similar physico-chemical properties often makes solvent selectivity requirements very tight. The shrinking list of safe solvents and ever tightening environmental regulations have made selective liquid solvents scarce.

Utilization of promising new technologies permits the imposition of conditions of quality and productivity that industry and academia are both interested to use. Our group has been involved mostly with two separation technologies – purely physical, pressure-driven membrane separation technology, which works on the basis of differences in size and shape of the molecules and supercritical fluid technology, which use benign solvents and is environmentally sustainable.

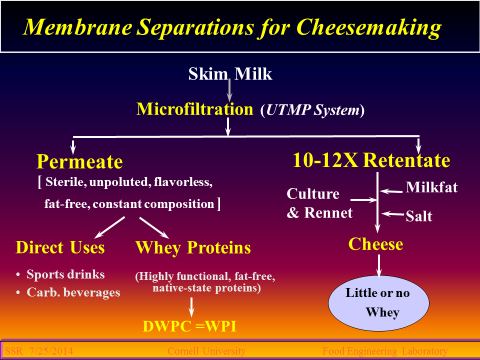

The impact of modern developments in membrane–based separations on food science and technology is well-established. It is arguably at its most obvious in the production of products in the dairy industry followed by other beverage industries. In our early work, we established the efficacy of removing whey protein from skim milk prior to cheese making and thus obtaining ‘virgin” whey. This approach obviates the need to clean up the conventional whey which, as a result of cheese making practices, gets contaminated with bacterial culture, salt, color and glycomacropeptides. On the other hand, concentrated casein fraction could be more efficiently utilized for cheesmaking, leading to an almost vatless manufacture operation.

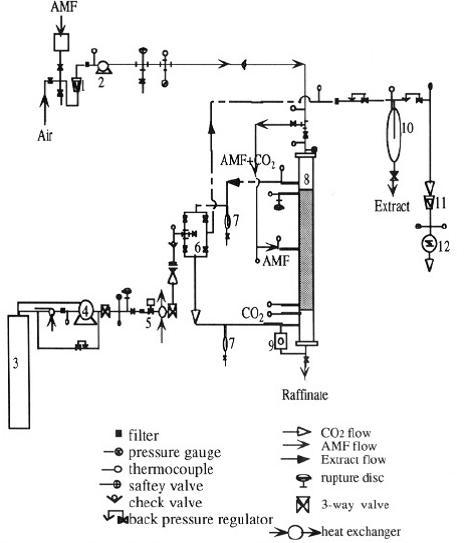

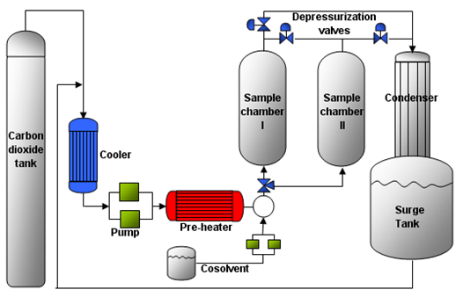

Fractionation of milk fat has been of interest to the dairy foods industry for a long time to enhance the utilization of milk fat. Our studies have shown the application of supercritical fluid extraction (SFE) for fractionation and cholesterol reduction of anhydrous milk fat (AMF) to offer attractive possibilities. However, inadequate thermodynamic descriptions of supercritical solvent-solute mixtures and lack of engineering data to facilitate scale-up and design have contributed to the limited acceptance of SFE processes on a commercial scale. Like most applications of SFE, research on milk fat has thus far concentrated only on batch systems. In the case of fluids like milk fat, which can be pumped at high pressures, it is reasonable to anticipate that the processing time can be minimized and the economics made more favorable by continuous processing. Our group designed and built a continuous system for the processing of anhydrous milk fat (AMF) with supercritical carbon dioxide (SC-CO2). The packed column was operated as a stripping column with SC-CO2 as the continuous phase and AMF as the dispersed phase. To utilize the functional similarities and make the analysis simpler, the AMF triglycerides were grouped as Fraction-1 (low-melting (LMT): C24-C34), Fraction-2 (medium-melting (MMT): C36-C40), and Fraction-3 (high-melting triglycerides (HMT): C42-C54). There was an increase in the concentrations of LMT and MMT and a decrease in that of HMT in the extract (Fraction-1 and 2). The raffinate (Fraction-3) had a high concentration of HMT with trace amounts of LMT. The performance characteristics of the packed column were described by the number of transfer units (NoG), the overall volumetric mass transfer coefficient (KoGa), and the height of a transfer unit (HOG).

Selected Publications- Marcelo, P. A. and Rizvi, S.S.H. 2008. Physicochemical properties of liquid virgin whey protein isolate. Int’l Dairy J. 18:236-246.

- Ardisson-Korat, A. V. and Rizvi, S. S. H. 2004.Vatless manufacturing of low-moisture part-skim Mozzarella cheese from highly concentrated skim milk microfiltration retentates. J. Dairy Sci. 87:3601-3613.

- Rizvi, S.S.H. and Bhaskar, A.J. 1995. Supercritical fluid processing of milk fat: Fractionation, scale-up and economics. Food Technol. 49: 90-97, 100.

- Rizvi, S.S.H. and Bhaskar, A.J. 1994. Continuous processing of milk fat with supercritical carbon dioxide. In: Developments in Food Engineering, T. Yano, R. Matsuno and K. Nakamura, Eds. Blackie Academic & Professional, London, p. 841-843.

- Shukla, A., Bhaskar, A.R., Rizvi, S.S.H. and Mulvaney, S.J. 1994. Physico-chemical and rheological properties of butter made from supercritically fractionated milk fat. J. Dairy Sci. 77: 45-54

- Bhaskar, A.R., Rizvi, S.S.H. and Harriott, P. 1993. Performance of a packed column for continuous supercritical carbon dioxide processing of anhydrous milk fat. Biotechnol. Prog 9: 70-74.

- Brandsma, R. and Rizvi, S.S.H. 1999. Depletion of whey proteins and calcium by microfiltration of acidified skim milk prior to cheese making. J. Dairy Sci. 82:2063-2069.

Cryogenic Freezing

Cryogenics engineering includes cooling and freezing of materials to very low temperatures using highly condensed gases like nitrogen, carbon dioxide helium, etc. In the food industry, liquid nitrogen is used to freeze foods quickly. In its liquid form, nitrogen, at -196°C, is one of the coldest substances that is often used to flash freeze fresh foods. As cryogenic freezing is much faster than mechanical freezing, products frozen with cryogenic technologies show a higher retention of water with a matrix of small ice crystals and retain their natural quality better.

Our current focus in this area involves Joule-Thomson expansion via adiabatic throttling which eliminates the need for elaborate mechanical refrigeration system and simplifies the equipment necessary. As the demand for value-added food product accelerates, there are many opportunities to further develop cryogenic technologies for food freezing and chilling applications. In particular, our group is engaged in designing and modeling a novel system that achieves instant freezing of products like ice cream and sorbet.