by Margaret Quaassdorff

On March 13th and 14th, a group of 23 farmers and small dairy processors from Western NY traveled with the CCE NWNY and SWNY Teams to successful farms and businesses who work within the value-added dairy processing space on the eastern side of the state. This trip was a result of a growing interest for locally produced specialty dairy products, and a desire from farmers to learn about options to diversify their dairy farm businesses.

Our farmer participants ranged in their experience and interest on the topic, with some farmers already producing on-farm value-added dairy products on their own, and some curious as to whether this type of enterprise may be right for them. The tour covered dairy farms large and small, as well as creamery partners, agri-service businesses, educational resources, and stores that specialize in NY products. Farmers received a packet containing information about available classes for safe and quality dairy food processing, grants available to dairy farmers and processors, business planning resources, etc. We were also fortunate to have Aljosa “Al” Trmcic from the Cornell Dairy Foods Extension Program join us on the tour to provide guidance and resources for processing and support offered by Cornell University.

Below is summary of the tour stops and some of the highlights from each:

Trinity Valley Dairy; Cortland, NY: Trinity Valley is a fourth-generation family farm in the beautiful valley of East Homer. The Moo Crew Ken and Sue Poole, Derek and Kelsi Poole and Branden and Rebekah (Poole) Brown run the farm. They milk Jerseys in both a parlor setting, and have a newer DeLaval automated milking system across the road. In 2013, they turned a sweet corn field into a milk production facility and general store that sells local products. Their farm is small and independent, bottles its milk onsite for their Trinity Valley brand and the Manhattan Milk Co. They made sure the group the group understood the importance and time it takes for marketing, and the benefits of having a variety of products available including creamline milk and different varieties of cheeses.

Trinity Valley Dairy; Cortland, NY: Trinity Valley is a fourth-generation family farm in the beautiful valley of East Homer. The Moo Crew Ken and Sue Poole, Derek and Kelsi Poole and Branden and Rebekah (Poole) Brown run the farm. They milk Jerseys in both a parlor setting, and have a newer DeLaval automated milking system across the road. In 2013, they turned a sweet corn field into a milk production facility and general store that sells local products. Their farm is small and independent, bottles its milk onsite for their Trinity Valley brand and the Manhattan Milk Co. They made sure the group the group understood the importance and time it takes for marketing, and the benefits of having a variety of products available including creamline milk and different varieties of cheeses.

- Byebrook Farm; Bloomville, NY: This 8th generation dairy farm milking 40 cows is operated by Paul and Gwen Deysenroth, and Dennis and Sami Deysenroth. They produce and bottle raw milk and make farmstead Gouda cheese in a variety of different styles, and operate a year-round farm stand with their products and other local farm goods. They talked about how producing one type of cheese with variations works well for them, and the opportunity of working with regional grant funding to develop their business.

Don’s Dairy Supply; South Kortright, NY: This full-service dairy supplier offers custom-made self-contained dairy processing units, other dairy equipment sales, installation, and support. It is owned by Don and Debbie Coager and their two children, Kyle and Brooke. Tour participants were able to walk-through the self-contained units, and learn about the cost, logistics, and opportunities surrounding small processing.

SUNY Cobleskill Dairy Processing Center; Cobleskill, NY. This facility is operated by the Institute for Rural Vitality of SUNY Cobleskill and allows dairy producers to apply for product development services and small-batch processing. The tour was led by Dairy Processing Center manager and educator, Debbie Brandt. Tour participants were able view a variety of processing equipment up close, and learn more about the steps involved, as well as regulations, of dairy processing.

SUNY Cobleskill Dairy Processing Center; Cobleskill, NY. This facility is operated by the Institute for Rural Vitality of SUNY Cobleskill and allows dairy producers to apply for product development services and small-batch processing. The tour was led by Dairy Processing Center manager and educator, Debbie Brandt. Tour participants were able view a variety of processing equipment up close, and learn more about the steps involved, as well as regulations, of dairy processing.

SUNY Cobleskill Carriage House Café; Cobleskill, NY: Short tour of the retail space and learning lab, by JoAnne Cloughly chair of SUNY Cobleskill’s Agricultural Business and Food Management program. Tour participants learned about the retail space and TasteNY store that highlights campus-made products and local farm goods. JoAnne offered insight as to how farmers may connect with stores that look to sell locally made goods. There was also discussion about the opportunities that come along with the NYS Grown and Certified Program.

SUNY Cobleskill Carriage House Café; Cobleskill, NY: Short tour of the retail space and learning lab, by JoAnne Cloughly chair of SUNY Cobleskill’s Agricultural Business and Food Management program. Tour participants learned about the retail space and TasteNY store that highlights campus-made products and local farm goods. JoAnne offered insight as to how farmers may connect with stores that look to sell locally made goods. There was also discussion about the opportunities that come along with the NYS Grown and Certified Program.

King Brothers Dairy; Schuylerville, NY: King Brother’s Dairy is a 5th generation dairy farm that offers milk delivery and an extensive farm store including ice cream parlor. Tour participants were able tour the registered Holstein dairy, and learn from Jan King, how to integrate the value-added processing enterprise into the farm. Many family members are involved with the entire farm and processing businesses, and each plays a key role. We were able to browse their farm store, and see the processing facility through viewing windows. Participants were also treated to two gigantic scoops of their choice of over 80 rotating homemade hard ice cream flavors.

Ideal Dairy; Hudson Falls, NY: Ideal Dairy Farms is owned and operated by the Dickinson and Getty families. Today they have a herd of 1,900 heifers and 3,200 mature cows and farm 4,500 acres in Washington and Warren Counties. They are also home of “Cookiecutter Holsteins” which is a well-known genetic line of high-producing and healthy cow traits. Tour participants walked the farm, viewed the rotary parlor, and learned that the farm puts value in being able to partner with Argyle Cheese as another means for a large dairy to maintain good contact with the community. Ideal Dairy works with Arglye Cheese to identify A2A2 cows and ship a portion of their milk for value-added processing.

Argyle Cheese; Hudson Falls, NY: Argyle Cheese is owned and operated by Marge and Dave Randles and was built in 2007 in Argyle. In 2020 they partnered with John and Denise Dickinson of Ideal Dairy to expand their operations and built a new processing facility in Hudson Falls. They now make high quality cheese, yogurts, buttermilk, smoothies, cheesecakes, and much more with milk from cows carrying the A2A2 gene. A2A2 milk contains proteins that are more digestible to those with protein sensitivities. Marge Randles gave a wonderful presentation about how her products are decided on and developed, as well as providing the tour participants with thought-provoking business questions regarding management and succession planning.

Argyle Cheese; Hudson Falls, NY: Argyle Cheese is owned and operated by Marge and Dave Randles and was built in 2007 in Argyle. In 2020 they partnered with John and Denise Dickinson of Ideal Dairy to expand their operations and built a new processing facility in Hudson Falls. They now make high quality cheese, yogurts, buttermilk, smoothies, cheesecakes, and much more with milk from cows carrying the A2A2 gene. A2A2 milk contains proteins that are more digestible to those with protein sensitivities. Marge Randles gave a wonderful presentation about how her products are decided on and developed, as well as providing the tour participants with thought-provoking business questions regarding management and succession planning.

A few farmer takeaways:

-Partnership with existing small processors and creameries may be a good way to go

-A way to bring more of the family back to the farm

-Ways to diversify as a small farm

-Next steps in making their current bottling process more efficient and scaled

-Great opportunity to network with other producers on the trip

-Ideas for new products and marketing

-Insightful tour that gave us an opportunity to think about if this is a good next step for us or not

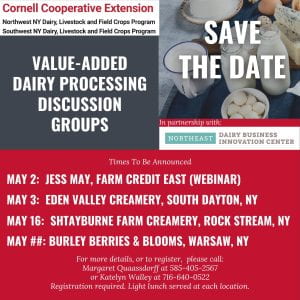

This educational, fun, and delicious trip was made possible with grant funding awarded by the Northeast-Dairy Business Innovation Center. Coming up, Katelyn Walley of the Southwest NY Team and I will be assembling discussion groups for any dairy farmers who are interested in taking the next step (whatever that is for them) in their value-added dairy processing journey. We have local value-added dairy processing business tours in the works, and discussion that will include resources to navigate financial strategies and state regulations. If you are interested in joining, please reach out to Margaret Quaassdorff at 585-405-2567 or maq27@cornell.edu for more information, as well as any additional topics you would like covered in this cohort setting.