One of the most frustrating things to a nutritionist, and indeed the cow herself, is a diet that is constantly changing. Just when a diet gets dialed in, it seems that a new bunk is being opened, first cutting is being buried behind a subsequent crop or an ingredient just ran out. Maintaining consistent forage content and quality in the diet is the basis for keeping other feed ingredients steady. Without knowing forage inventory, the task of maintaining consistency becomes almost impossible over a year’s time. This year especially, with drought affected later hay crop cuttings and many corn fields being frosted early, paying attention to inventory of all forages now will ensure diet consistency through the winter months.

Where to Start? What are Forage Needs?

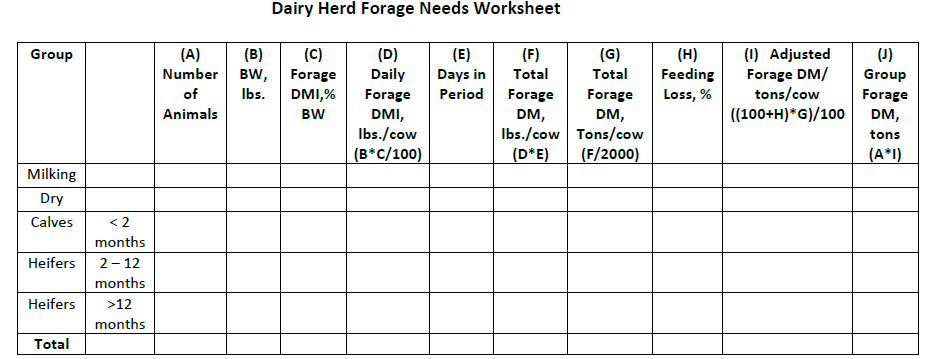

The first step for identifying inventory needs is to determine forage needs for the entire herd. Cornell Cooperative Extension published a Dairy Herd Forage Needs Worksheet several years ago that still applies, and I adapted it to an Excel spreadsheet so numbers can be easily plugged in and calculated.

Key points to determining forage needs are:

- the number of animals in each group

- the average body weight of the group of animals

- the time frame in days that inventory needs to last

Another factor that comes into play is the forage dry matter intake, as a percent of body weight. For this purpose, lactating cows can be calculated between 1.5% to 2.5%, dry cows 1.2% to 1.7%, and heifers 1.0% to 2.0%. Feeding losses are another factor, and should be considered between 5-10% at minimum. For round bale feeding through feeders or other potential ways of feeding that experience loss, a higher percent may be necessary.

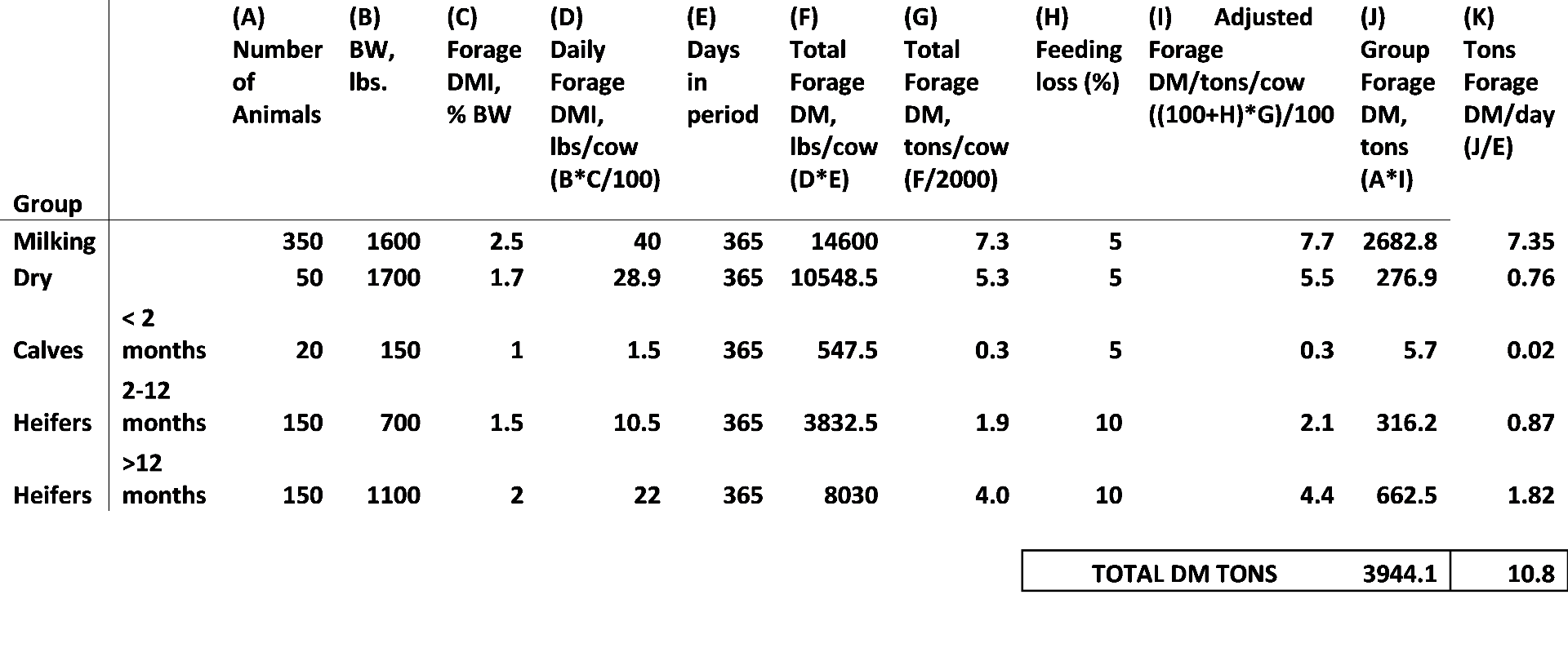

Once you’ve worked through the process for each group of animals, the total forage tons (in dry matter) can be calculated for the time period selected, or per day. Key to this is remembering that this is dry matter tons, not as fed tons. See Figure 2 for an example for a 400 cow herd.

Determining Forage Inventory

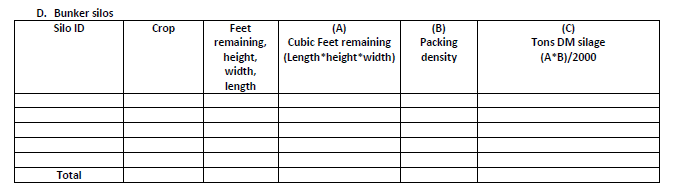

After forage needs have been determined, forage inventory can be calculated. All bales of dry hay, (round and square), bales of baleage (round and square), haylage and corn silage in upright silos, bunk silos, ag bags and drive-over piles should be considered and calculated. The key to determining forage inventory, especially with bunk storage, is to not overestimate the packing density. If you’re not sure of the density, there are methods to assess this. Good rules of thumb that can be applied are 12 lb DM/cubic foot = poor packing, 15 lb DM/cubic foot = average packing, 18 lb DM/cubic foot = excellent packing. In some cases over 20 lb DM/cubic foot can be achieved, but I would hesitate to use this number without verifying. Several years ago Cornell Cooperative Extension developed worksheets to assist in this process that I again adapted to Excel sheets, and can be shared.

Finally, Matching Inventory to Needs

The last step to answering the question of adequate forage inventory involves matching forage needs to inventory. A simple subtraction of needs from inventory tells us whether there is an adequate supply or not for the time frame used in the forage needs worksheet. In this example, our forage needs worksheet used a full year of days to calculate needs, and while this probably is true for corn silage in most situations, many farms do not carry over a full year of haylage. Adapting our forage inventory table to determine the days required for the forage to last will tell us if we have adequate inventory over the time frame. For example, if our corn silage inventory equals 2500 DM tons and we want it to last a full year, we can expect to feed up to 6.85 DM tons per day and make it last. If our first crop haylage inventory equals 500 DM tons and we need it to last 200 days, we can expect to feed up to 2.5 DM tons per day for it to last that time frame. In figure 2, I added a last row that calculates forage needs per day. For each forage type, we can match to the animal class that will eat it, and calculate if needs are met by inventory over time frame. In our example (figure 2) lactating cows need a total of 7.35 DM tons per day. Our inventory of 2500 DM tons of Corn silage and 500 DM tons of first crop is adequate for our lactating cow needs, but the forage needs of other animal classes must be added to those numbers to be sure there is enough inventory of each forage.

Key Side Note

Shrink is not included in any forage needs numbers, other than feeding losses. Forage inventory numbers also do not take into consideration any shrink amount. Even if there is minimal visual spoilage in a pile, some amount of shrink is probably occurring. Evaluating inventory several times throughout the year is worthwhile to account for this, especially if there is significant spoilage on the sides or tops of piles.

Tedious, but Worthwhile

Nothing is more concerning than watching a pile of corn silage disappear faster than anticipated, other than perhaps running out of said forage. Taking the time to evaluate inventory in the fall, after harvest of all crops is necessary to set the stage for feed-out over the winter months. Another good time to re-evaluate inventory and adjust feed-out rates is around the first of the year. Small changes are better than large changes, and involving the nutritionist to evaluate inventory during set time periods over the course of the year will ensure that the farm, the nutritionist and the diet are all on the same page. Your Extension Educator can also help walk you through the process, we’re only a call away. The cows will thank you for it.