Bioseparation steps often pose the greatest impediment to scale-up and commercialization of a process. Bioseparations using conventional techniques (distillation, absorption, solvent extraction, etc.) are often impractical because many biomaterials are of high molecular weight, have very low vapor pressure and are often unstable at elevated temperatures. The separation of multicomponent mixtures of similar physico-chemical properties often makes solvent selectivity requirements very tight. The shrinking list of safe solvents and ever tightening environmental regulations have made selective liquid solvents scarce.

Both industry and academia are interested in utilizing new separation technologies with the promise of providing higher quality and better productivity. Our group has been involved mostly with two separation technologies:

- Purely physical

- Pressure-driven membrane separation technology

- Selectively excludes/includes molecules based on size and shape

- Supercritical fluid technology

- Benign solvents

- Environmentally sustainable

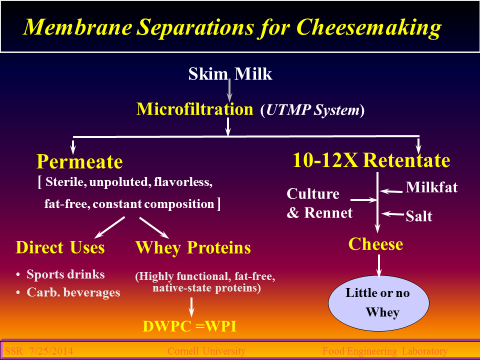

The impact of modern developments in membrane-based separations on food science and technology is well established. It is arguably at its most obvious in the production of products in the dairy industry followed by other beverage industries. In our early work, we established the efficacy of removing whey protein from skim milk prior to cheese making and thus obtaining ‘virgin” whey. This approach obviates the need to clean up the conventional whey which, as a result of cheese making practices, gets contaminated with bacterial culture, salt, color and glycomacropeptides. On the other hand, concentrated casein fraction could be more efficiently utilized for cheese making, leading to an almost vat-less manufacturing operation.

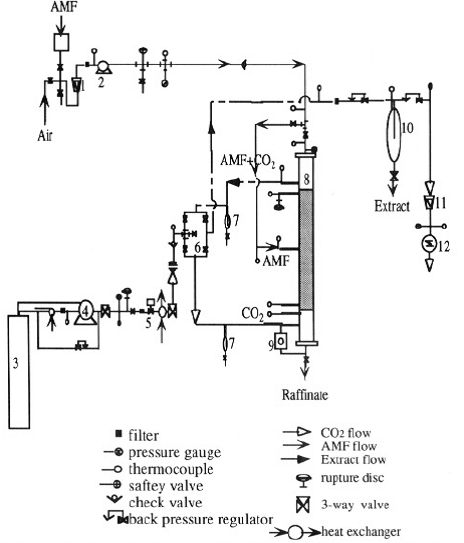

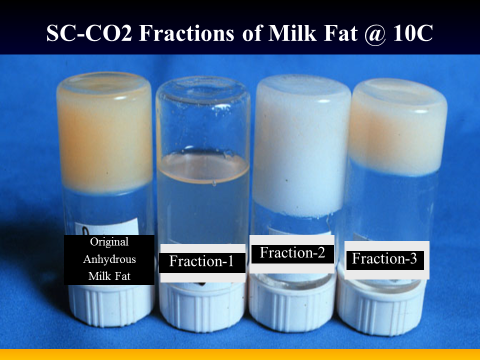

The dairy foods industry has been interested in enhancing the utilization of milk fat by employing better fractionation for a long time. Our studies have applied supercritical fluid extraction (SFE) to fractionation and cholesterol reduction of anhydrous milk fat (AMF) and show attractive possibilities. However, inadequate thermodynamic descriptions of supercritical solvent-solute mixtures and lack of engineering data to facilitate scale-up and design have contributed to the limited acceptance of SFE processes on a commercial scale. Like most applications of SFE, research on milk fat has thus far concentrated only on batch systems.

In the case of fluids like milk fat, which can be pumped at high pressures, it is reasonable to anticipate that the processing time can be minimized and the economics made more favorable by continuous processing. Our group designed and built a continuous system for the processing of anhydrous milk fat (AMF) with supercritical carbon dioxide (SC-CO2). The packed column was operated as a stripping column with SC-CO2 as the continuous phase and AMF as the dispersed phase. To utilize the functional similarities and make the analysis simpler, the AMF triglycerides were grouped as Fraction-1 (low-melting (LMT): C24-C34), Fraction-2 (medium-melting (MMT): C36-C40), and Fraction-3 (high-melting triglycerides (HMT): C42-C54). There was an increase in the concentrations of LMT and MMT and a decrease in that of HMT in the extract (Fraction-1 and 2). The raffinate (Fraction-3) had a high concentration of HMT with trace amounts of LMT. The performance characteristics of the packed column were described by the number of transfer units (NoG), the overall volumetric mass transfer coefficient (KoGa), and the height of a transfer unit (HOG).

Selected Relevant Publications:

- Marcelo, P. A. and Rizvi, S.S.H. 2008. Physicochemical properties of liquid virgin whey protein isolate. Int’l Dairy J. 18:236-246.

- Ardisson-Korat, A. V. and Rizvi, S. S. H. 2004.Vatless manufacturing of low-moisture part-skim Mozzarella cheese from highly concentrated skim milk microfiltration retentates. J. Dairy Sci. 87:3601-3613.

- Brandsma, R. and Rizvi, S.S.H. 1999. Depletion of whey proteins and calcium by microfiltration of acidified skim milk prior to cheese making. J. Dairy Sci. 82:2063-2069.

- Rizvi, S.S.H. and Bhaskar, A.J. 1995. Supercritical fluid processing of milk fat: Fractionation, scale-up and economics. Food Technol. 49: 90-97, 100.

- Rizvi, S.S.H. and Bhaskar, A.J. 1994. Continuous processing of milk fat with supercritical carbon dioxide. In: Developments in Food Engineering, T. Yano, R. Matsuno and K. Nakamura, Eds. Blackie Academic & Professional, London, p. 841-843.