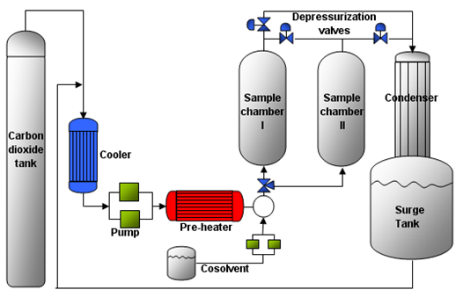

Although the American food safety record is among the very best in the world, batches of ground beef, sprouts, peanut butter, pistachios, spinach, and even cookie dough have been implicated in serious outbreaks in recent years. We are currently evaluating the use of benign and environmentally friendly supercritical fluids (SCF) like carbon dioxide, nitrous oxide, etc. as food safety decontamination processes of commercial utility. Although more sophisticated than many of the currently used commercial sterilization techniques, SCF-based sterilization technology is ideally suited for hard-to-decontaminate, low-volume, high-value commodities like seed sprouts and nuts and selected meats. SCFs present unique advantages since they can easily penetrate cracks and crevices due to high diffusivity and low surface tension. It could reach uniformly at all sites within the seeds as well as on the seed surface, thereby targeting on-surface as well as internalized pathogens. We plan to investigate the effects of superimposed dense gas process variables (pressure, temperature, additives) and their mechanism of interactions for inactivation of microorganisms and enzymes in model and real food matrices and develop physically realistic models and correlations to accurately quantify the experimentally observed responses.

Selected Relevant Publications:

- Adi, M.S., Zoellner, C. and Rizvi, S.S.H. 2013. Current Intervention Strategies for the Microbial Safety of Sprouts. J. Food Protection, 76:2099–2123.

- Iftikhar, T., Wagner, M. E. and Rizvi, S. S. H. 2014. Enhanced inactivation of pectin methyl esterase in orange juice using modified supercritical carbon dioxide treatment. Int’l J. Food Sci. Technol, 49: 804–810

- Zoellner, C., Rizvi, S.S. H and Worobo, R. 2014. Decontamination of alfalfa sprout seeds contaminated with E. coli O157:H7 using supercritical carbon dioxide and peroxyacetic acid hurdle treatment. In review.