Time for a new tip

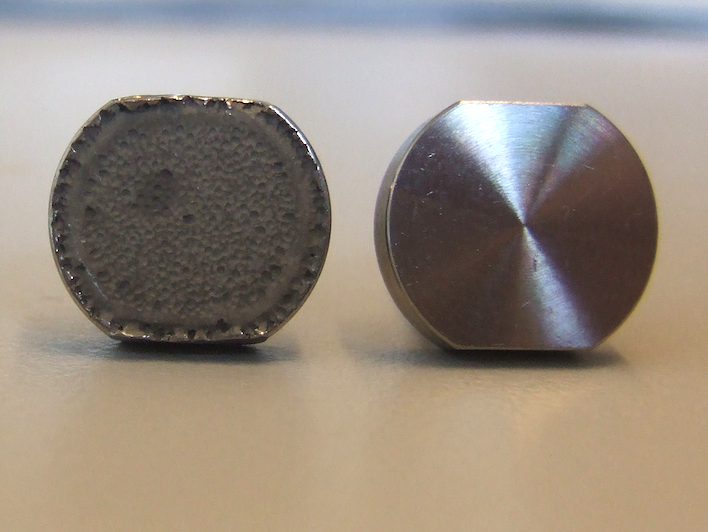

Take a look at these two flat sonicator tips:

To quote from the manual:

“The radiating face of replaceable tips and solid horns is subjected to intense bombardment by shock waves from cavitation implosions. Roughening the surface area accelerates the rate of erosion. The radiating face can be smoothed with fine emery paper. If allowed to erode further, until pitted, the horn or tip will be damaged beyond repair. Do not file, grind, or lathe down tips, horns, or mating surfaces. Retune unit after smoothing tip. Flat tips badly burred by improper

wrenching should be replaced.”

Interestingly, checking which tip to order for a replacement isn’t so straightforward. As is common for lab equipment, this one is branded Fisher, a major R&D supplier. But this company doesn’t actually manufacture the item and knows nothing about its operation and maintenance. Furthermore, Fisher no longer even stocks this model (Model 550). It turns out that the machine is manufactured by Branson Ultrasonics corporation, and yet another company, Process Equipment & Supply, Inc. sells the parts. Hey, it’s 2010.

Interestingly, checking which tip to order for a replacement isn’t so straightforward. As is common for lab equipment, this one is branded Fisher, a major R&D supplier. But this company doesn’t actually manufacture the item and knows nothing about its operation and maintenance. Furthermore, Fisher no longer even stocks this model (Model 550). It turns out that the machine is manufactured by Branson Ultrasonics corporation, and yet another company, Process Equipment & Supply, Inc. sells the parts. Hey, it’s 2010.

Once past the intricacies of equipment manufacture and supply, we needed to figure out which was the correct replacement accessory for the model in the lab. The tip we need is 1/2 inch flat tip, 1/4-20 thread, Branson part number 101-148-013 which could be confirmed as we still had the original packing information with the previous tip. This was lucky, as a cursory measurement of the tip itself is ambiguous, being 7/16 inch on one side and 1/2 inch when rotated 90?.