RESEARCH SPOTLIGHT: Characterization of Sensory Profiles of Yogurt Acid Whey Fermented with Five Different Yeasts

This week, we are highlighting the work of MPS student, Rossie Luo. If you have been following along with the research spotlights, you may have noticed that ARG does a lot of research investigating novel fermentations of dairy effluents to valorize waste products and create a more sustainable process. But how do these fermented beverages actually taste?? Rossie’s research sets out to answer that question!

Rossie’s work is centered around evaluating the sensory profile of fermented beverages made from yogurt acid whey. Unlike sweet whey that can be used to make whey protein powder, yogurt acid whey typically has limited value-added applications and is mainly used as animal feed or as a fertilizer. Yet, acid whey still has residual lactose, making it a suitable substrate for yeast fermentation. The goal of her research is to ferment yogurt acid whey with five different yeasts to evaluate the sensory profiles that each yeast creates during fermentation.

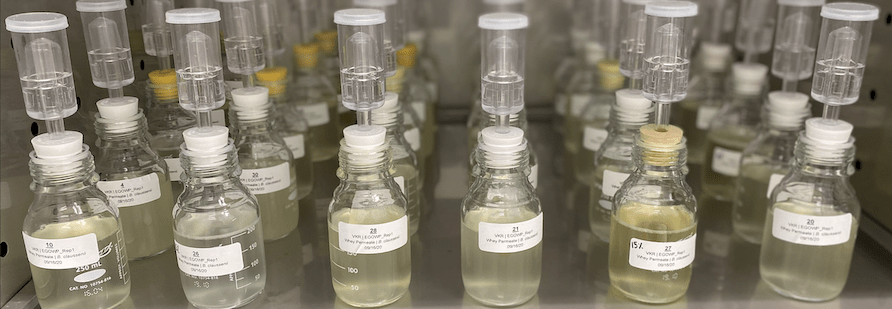

To do this, Rossie set up fermentations with five different yeast strains and monitored the density, pH, and cell concentration throughout the duration of the fermentation to characterize the fermentation profiles of each yeast. She also compared the sugar, ethanol, and organic acid concentration at the beginning and end of fermentation for each yeast. What she saw is that each yeast creates a unique fermentation profile for the yogurt acid whey!

Once the fermentations were complete, she set out to characterize the sensory profiles of each beverage prototype. Through the Sensory Evaluation Center at Cornell, a focus group was conducted and was followed by an individual questionnaire. During the focus group, participants were guided to discuss various aspects of their sensory perception of the beverage prototypes such as aroma, flavor, mouthfeel, and aftertaste. A list of sensory descriptors was then generated and used as metrics for the individual questionnaire to evaluate the prototypes. It turns out that these yeasts were able to impart different and unique flavors to the fermented yogurt acid whey!

This study provides important insights that can guide further product development of a fermented acid whey beverage. It is exciting to think that we can be part of a more sustainable future with delicious and nutritious fermented yogurt acid whey beverages!

[1] Siyi (Rossie) L, Timothy A. D, Dana D, Samuel D. A. (2021) Characterization of the Fermentation and Sensory Profiles of Novel Yeast-Fermented Acid Whey Beverages. (manuscript in preparation).