RESEARCH SPOTLIGHT: Optimizing alcoholic fermentations to develop new products from whey permeate

This week, we are highlighting the work of PhD student, Viviana Rivera Flores. Viviana is working on optimizing the fermentation process of whey permeate under anaerobic conditions to develop low-alcohol beverages with potential functionality. Whey permeate is the dairy effluent that results after obtaining protein concentrates from cheese whey. For every pound of cheese produced, about seven and a half pounds of permeate are created.

While whey permeate has gained attention in the food industry as an additive, novel biomanufacturing technologies can open avenues for greater valorization of this product. In oxygen-deprived atmospheres, yeast can convert lactose from this substrate into ethanol and galactose, offering a sustainable and flexible alternative. Galactose acts as a prebiotic precursor and provides energy without altering our sugar balance, hence a beverage with this sugar would have functional properties. On the whole, anaerobic fermentation of whey permeate is a versatile process from which we can generate bioethanol, recover galactose, or develop novel beverages. Three possible products from only one raw material!

General steps of her methodology include substrate preparation, yeast propagation, fermentation experiments, product analysis, optimization model development, and further process optimization.

Currently, Viviana is working on the optimization model of the fermentation process. She is evaluating the impact of different parameters (like temperature and time) on ethanol and galactose concentration. To make this possible, she works with a software that builds statistical models that take multiple factors to optimize the desired products. For better optimization, this software uses a design called response surface methodology, which is an efficient way to assess the individual impact of each fermentation parameter and understand their interactions. If ethanol and galactose are maximized, more efficient valorization and better functionality of this waste stream can be achieved.

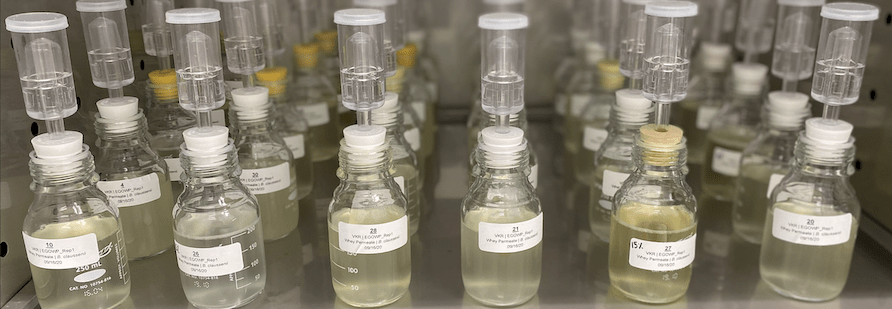

To accomplish this, she has been running benchtop scale fermentations with multiple combinations of fermentation factors. This has led to over 160 individual fermentations!

So far, her results demonstrate that it is possible to adjust multiple parameters to maximize ethanol and galactose production from whey permeate. Once she finalizes the process optimization stage, her next steps will be to explore different formulations to develop a novel beverage and investigate this process at larger scales.

So, if you are a health-conscious consumer looking for a better-for-you, refreshing hard seltzer that’s also committed to a more sustainable environment, stay with us!