RESEARCH SPOTLIGHT: Using Lactose Oxidase as a natural antimicrobial to inhibit growth of Listeria monocytogenes in Queso Fresco

This research spotlight highlights the work of master’s student Brenna Flynn. Brenna is investigating whether a naturally derived enzyme, lactose oxidase, can inhibit the growth of Listeria monocytogenes in queso fresco. Listeriosis is a high-risk infection caused by the consumption of L. monocytogenes which predominantly affects those with compromised immune systems, pregnant women, and the elderly. It also has a high lethality rate which makes it a main cause for concern in food safety.

L. monocytogenes is a problem for the dairy industry because it commonly contaminates products after pasteurization. Many dairy products are ready-to-eat (RTE), meaning that there’s no further kill step after pasteurization to reduce Listeria counts before the consumer eats the product! In addition, queso fresco has a near-neutral pH with a high water content, making it an ideal environment for pathogens to thrive if the cheese becomes contaminated. In ARG, we are trying to find an effective control method to reduce or eliminate L. monocytogenes in queso fresco to mitigate future L. monocytogenes outbreaks and keep consumers safe!

With increased consumer demand for clean-label ingredients, enzymatic antimicrobials can be an option for producers. Lactose oxidase is a naturally derived enzyme that oxidizes the sugar in milk, lactose, into lactobionic acid, while reducing oxygen into hydrogen peroxide. This reaction is an activator of a native antimicrobial system in milk. Hydrogen peroxide itself is also a widely used antimicrobial that is generally recognized as safe at low concentrations in food. In previous studies, hydrogen peroxide has shown to be an effective inhibitor of L. monocytogenes in queso fresco.

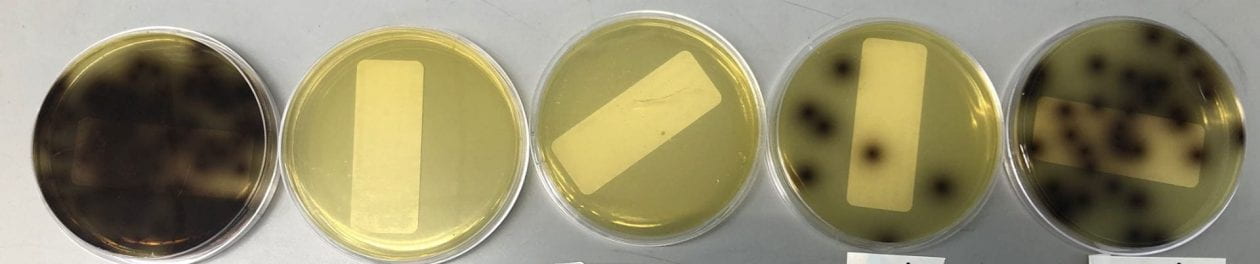

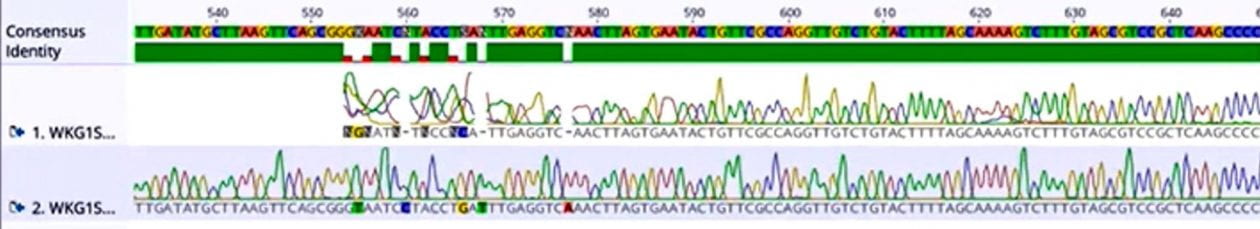

Brenna has been making lab-scale queso fresco to test if lactose oxidase has antimicrobial properties. She has run multiple experiments, using lactose oxidase as both an additive to the milk during the cheesemaking process and as a topical application. She then inoculates the cheese with L. monocytogenes to determine if lactose oxidase has an antimicrobial effect.

So far, her experiments have shown that lactose oxidase is effective at inhibiting the growth of L. monocytogenes! Lactose oxidase could potentially be used as an antimicrobial in the dairy industry to keep consumers everywhere safe!