This past week we got the chance to get out of New York again and go out to Pontiac Illinois to Precision Plantings new 200 acre test farm. This was a great opportunity for training on Precision Plantings new product as well as meeting other dealers from across the country. The day of training consisted of two different parts the first being the ride and drive time in what they called the sandbox and then the agronomy tour. The ride in drive was great with precision planting recently being bought by AGCO they had a brand new line up of equipment for us to try all the different precision planting products on. The agronomy tour took us throughout the farm showing us each plot and new things that were in the works for precision planting. It was a great trip learning the benefits of each product and where they can be best implemented.

Precision Technology Institute

Summer Summary

I have had an amazing summer interning at Kreher Family Farms! As my internship came to an end, I couldn’t express my appreciation enough for all the opportunities I was provided with this summer. My last week was bitter sweet because I was so thankful for all the opportunities I was provided with but sad to leave and not see the completion of harvest (why isn’t corn a 45 day crop???). I want to utilize this post to reflect on my amazing summer and all the opportunities I was provided with.

During scouting, I was able to find some unique things such as these two leaves that had actually fused together at the stem to form a funnel shape!

One of the highlights of my summer included being involved in

These little guys make themselves right at home, even though they aren’t exactly welcome!production!

field and vegetable crop. It is not everyday that you are able to experience an organic farm that not only grows field crops but also approximately 600 acres of vegetable crops. I was able to scout fields for insect and weed pressure along with conducting yield estimates. In some fields, specifically beets and corn, we took tissue and soil samples at various growth stages and sent them out for nutrient analysis. It was very neat to see the results of these samples and be able to make connections about why the results were what they were. For example, the drought stress our corn experienced in the beginning of July was visible when compared to the irrigate corn sample from right across the street! In the beets, we were paying particular attention to the boron levels in the tissue samples because beets require a high level of boron and we wanted to apply foliar boron applications at the correct time.

Mechanical cultivation is crucial in organic production. This is a six row cultivator with row guards in place, cultivating twin row planted beets.

I also had the pleasure of being involved in some planning meetings about next years crop plan and this winters cover crop plan. It was important for us to keep in mind the desired rotation but also considering where we were experiencing high weed pressure and should be utilizing cover crops to decrease weed pressure in future seasons. Other things to keep in mind while planning for the future included availability of irrigation, soil type, and proximity to the main farm location.

Finally, I would like to reflect on my experience with being involved in audits that occur on the farm. In the moment, preparing for and completing an audit may not be the most enjoyable experience but now that I look back on them, I was able to learn a ton from the experience. During my times at Kreher’s, we completed our NOFA-NY Organic audit and a GLOBAL G.A.P. Food safety audit. These audits were both very different but each serve there own purpose. GLOBAL G.A.P. focuses on food safety in the vegetable crops. The auditor wanted to make sure we were following proper procedures to ensure a safe product at the end. Some things she looked at included records of sampling irrigation water and testing it for E. coli along with other potential contaminates. They also wanted to see records of equipment cleaning to make sure that was occurring at appropriate intervals to prevent food safety issues.

Overall, my experience at Kreher Family Farms was extraordinary and I could not have asked for a better experience. I was able to experience a one of a kind large scale crop and poultry operation and make connections that I hope will last past these three summer months.

Goodbye Hops, Hello Grapes

The last few weeks have been spent preparing for harvest. Mite counts have increased in various fields and scouting densities have slowly decreased in the fields that haven’t had as much activity. Brewers and researchers have been busy visiting the farm in preparation for the upcoming months. I had the chance to attend a meeting with Yakima Chief Hops (formerly Yakima Chief HopUnion) with salesmen and women who work for YCH. At this meeting, Jason Perrault, the CEO of Perrault Farms, Inc. and Yakima Chief Ranches (formerly known as Select Botanicals Group), gave a speech regarding the various new experimental varieties YCR has been developing and how they will affect growers and brewers. Citra® has since been listed as the number one hop variety used in beer, surpassing Cascade which has been the leader for many years.

The last few weeks have been spent preparing for harvest. Mite counts have increased in various fields and scouting densities have slowly decreased in the fields that haven’t had as much activity. Brewers and researchers have been busy visiting the farm in preparation for the upcoming months. I had the chance to attend a meeting with Yakima Chief Hops (formerly Yakima Chief HopUnion) with salesmen and women who work for YCH. At this meeting, Jason Perrault, the CEO of Perrault Farms, Inc. and Yakima Chief Ranches (formerly known as Select Botanicals Group), gave a speech regarding the various new experimental varieties YCR has been developing and how they will affect growers and brewers. Citra® has since been listed as the number one hop variety used in beer, surpassing Cascade which has been the leader for many years.

Following Jason’s speech, Amy Matthews, the Brand Manager at YCR, discussed patents and registered trademarks. I thought the information she provided was very interesting. With hops, a variety has a “code” which the hop is patented under. This code describes the characteristics which make that specific hop unique, allowing a company to patent it. However, separate from the code is the brand name which receives the registered trademark. For example “Ekuanot®” is the brand name of this hop and “HBC 366” is the patent name. Therefore, she wants the salesmen and women at YCR to refer to hops only by their brand name since this is what is trademarked and will be used when marketing the product.

Finally, Jeff Perrault gave a presentation on pre-season through post-harvest operations which included information on planting new fields, training bines, IPM, pesticide application, harvest operations and preparation for the winter.

The last nit of our work at the farm has included the completion of sap analysis, scouting of fields, and roguing. We have been going back through fields that we have rogued and have been using biodegradable survey spray paint to mark the male hills. This will make it easier for our supervisor to remove male hills after harvest. Below is an image of hops that were pollinated by a neighboring male plant. These hops caught my eye because of their large size due to containing seed.

Last weekend I had the opportunity to attend the Moxee Hop Festival where I saw this hop picker that was used in the fields back in the 1940’s. A hop picker is used to separate the leaves and woody material from the cones. It is incredible to see the technology that was used back then and compare it to what is being used today!

I complete this post with the last sunrise I will be seeing at the farm. I’m excited to announce that for the last two weeks of my internship, I will be working at Two Mountain Winery in Zillah, WA developing an IPM plan that they can continue to use in their vineyards in future years!

Scouting Green Beans

Green beans are a very big market here in Western NY with the majority of them being processed through the Seneca foods plant in Geneva.  That being said, it is very important to be out scouting those fields weekly checking for insects, disease, and weed pressure. Throughout the summer at least one day a week I get the chance to get out and either scout green beans or sweet corn; both destined for canning. This week I was out walking green bean fields that were spread across the state from Utica to Buffalo. While walking fields, I am mainly focusing on weed pressure as well as white mold and insects. With this summer being so dry in western NY I have still yet to find any white mold. I hope for the growers sake it stays that way. It’s important while I am out scouting that I am checking growth stages of the plants throughout the entire field so that no herbicide or pesticides are applied too late and can damage growth further.

That being said, it is very important to be out scouting those fields weekly checking for insects, disease, and weed pressure. Throughout the summer at least one day a week I get the chance to get out and either scout green beans or sweet corn; both destined for canning. This week I was out walking green bean fields that were spread across the state from Utica to Buffalo. While walking fields, I am mainly focusing on weed pressure as well as white mold and insects. With this summer being so dry in western NY I have still yet to find any white mold. I hope for the growers sake it stays that way. It’s important while I am out scouting that I am checking growth stages of the plants throughout the entire field so that no herbicide or pesticides are applied too late and can damage growth further.

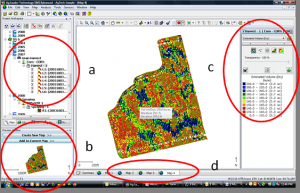

Yield Data Cleaning and Taking Flight

In working along with my supervisor, I have been able to get a feel for yield data cleaning. It is a very important part in the Nrich strip project. A yield monitor is used on the harvester to record the information. But the yield is not totally until it is cleaned. The raw data arrives from the farm and is then loaded into SMS. SMS is the software that is used to configure the field boundaries. The files are then transferred to a software called Yield Editor. The moisture and flow delays are checked and any outlying values are deleted. Once a field has its yearly yield data cleaned it is ready to be used in Arcmap. By using classify and raster calculator tools, the quadrant is made to evaluate the best area for Nrich implementation.

Well, a new drone finally arrived! It’s really exciting to see the new drone fly in the air. The speed is remarkable. It requires only a few presses of the button on the tablet to fly. It took eleven minutes to fly a 105 acre field. During the flights, the camera records Normal Digital Vegetative Index. The values will be used in a formula to predict yield. The best time for flying is when the plants are at stage V12 in order to draw the most accurate estimates.

Northeast Weed Science Society contest

As part of the internship experience I participated in the NEWSS Collegiate Weed Science Contest. The contest was held in Smithfield, North Carolina on July, 24 hosted by BASF. Starting in June our team of 11 people had weekly meetings from 5:00 pm to 7:00 pm on Tuesdays. During practice we went over the rules, practiced identification, went over unit conversions and talked about past experiences. The most helpful experience was doing weed walks in the Weed Teaching Garden and looking at flats with herbicide symptoms. More details of the layout of the contest are given here: https://blogs.cornell.edu/sips/2018/08/05/cornell-students-excel-at-collegiate-weed-contest/

As a visual and tactile learner, identifying weeds as part of my job was very appealing and was a great way to practice for the contest. One of the projects that I helped identify weeds for was a project looking at the effects of deer browsing on weed communities. I worked on this project on rainy days because the flats were inside the greenhouses. When the weather was nice I counted weed seedlings at Musgrave and Freeville as part of the weed seed bank emergence forecasting project. The purpose of forecasting is to help identify weeds that farmers might have in their fields. In these plots there we’re subplots that were tilled and not tilled. I also practiced by memorizing scientific names.

Two days before the contest the we drove 10 hours from Ithaca to Smithfield. The plan was to have a day to practice before the competition. The morning after arriving we went for a walk to identify weeds found in southeastern United states that we had not seen before. Then we did a complete walk through of the sprayer calibration. My role was to do the timed walk through after the calculations, backpack, and nozzles were in place. In the afternoon we went over the farmer problems list that was given to use in advance. Each of us researched a problem and identified root causes and possible solutions.

The day of the competition weed identification was first. I managed to identify some, but others I was less confident about or I couldn’t remember the name. Next was the calibration. For the sprayer component I had to walk 50ft in 10 seconds with the sprayer 30 inches above the ground. I forgot to start spraying the first time I made the walk, so the judge let me restart the walk. The walk was perfect except for the mishap the first time. Next was the 20 minute written test that had many conversions. During the farmer problems, it would have been more clear to me how to approach the problems If I had practiced reading herbicide labels more. However, I knew the solution to one of problem thanks to the research. The second farmer problem I was able to find out that the farmer dumped extra herbicide in the forested area. It was easy to tell that there was bleaching. Overall the contest was thrilling and I look forward to participating in the Weed Olympics in my home state of Illinois next year!

Orchard Weed Research Project

One of the research projects at the orchards that I have assisted with is collecting weed samples in the orchard. This research project is being conducted under Honey-crisp trees grafted on a Bud 9 rootstock managed in an organic system. The bud 9 rootstock is cold-hardy and has a dwarfing effect on the honey crisp variety, and the trees are planted onto a high density system. Research for this project started in 2016, and contains different treatment practices for weed control and soil health. The treatments include mulch, tilling with an implement by Harris Mackey called the Wonder Weeder, weed whacking, 2 organic sprays (Suppress and Final-San-O) and a control area. Ultimately, the research project aims to see which weeds grow under different management systems, the biomass of those weeds, which system yields higher soil health levels, and the overall horticultural performance of different management systems.

One of the research projects at the orchards that I have assisted with is collecting weed samples in the orchard. This research project is being conducted under Honey-crisp trees grafted on a Bud 9 rootstock managed in an organic system. The bud 9 rootstock is cold-hardy and has a dwarfing effect on the honey crisp variety, and the trees are planted onto a high density system. Research for this project started in 2016, and contains different treatment practices for weed control and soil health. The treatments include mulch, tilling with an implement by Harris Mackey called the Wonder Weeder, weed whacking, 2 organic sprays (Suppress and Final-San-O) and a control area. Ultimately, the research project aims to see which weeds grow under different management systems, the biomass of those weeds, which system yields higher soil health levels, and the overall horticultural performance of different management systems.

To collect data, we first place square outline of PVC pipes on the ground between trees. After the target area is defined, my supervisor would take a picture of the area to collect data on the percentage of weed cover in the plot. Next, we cut the weeds at surface level, and then sort them out into bags labeled with their variety. We would then dry the weeds and weigh them to note the biomass levels. I have not tested soil health, but soil samples are sent to the Soil Health lab at Cornell to assess this data point. This process is repeated every month to see the change in varieties and repeated across many rows in the orchard to account for different factors that could be present across rows and trees.

This diagram shows what area we would harvest weeds from in the orchard. Some plots have much more weeds than this and many more varieties. This research project has been useful in my ability (or lack thereof) to identify weeds that grow in the area! This plot looks like could be part of the organic spray section, but I am unsure which spray was used in this area.

In this picture, you can see the difference in weed biomass and species that are present in the research trial. I would guess that this section would be in the “control’ category, meaning that we have not had any weed control interference in the plot. These weeds are most likely competing with the trees for nutrients and could grow to be very unruly if left alone.

The following picture is the mulch section of the trial. From my observations, this treatment seems to prevent weeds the best when compared to the other treatments.

The next picture is of the “Wonder Weeder” plots. This cultivation implement is attached to the front of the tractor, and the speed is dictated by the speed of the tractor. Cultivation with this tool is fairly shallow, so the soil health levels are not majorly impacted. My supervisors like this tool for orchard weed management, because it allows them to get close to the trees and see the area they are tilling from the front hitch attachment. I have also attached an image of the implement to get a better idea of what it looks like.

photo-MSU Extension

photo-MSU Extension

After we weigh the weeds, we input the data into a excel spreadsheet that is formulated to allow my supervisor to see how much of the biomass was composed of which species. Hopefully later, they will be able to share scientific-based recommendations on which weed control method prevents certain weeds and total weed cover for organic apple orchards!

Hairy Vetch: Managed or Management Practice?

Hi all, my name is Matthew Spoth and this summer I am interning for Matthew Ryan in the Sustainable Cropping Systems Lab. The summer is flying by and it is probably because of how much fun I have been having at work. Every week I am assisting with a different task, and it is exciting to watch all of our research plots progress.

Perennial Grain plot where we managed the vetch by hand weeding to keep the farmers happy!(vetch is the purple color you can see)

Over the next several decades, our environmental stability is going to diminish due to changes in climate. Concurrently, our global population and the demand for production will be exponentially increasing. As a brief overview, the lab focuses on advancing sustainable crop production practices. We do this through researching radical and exciting ideas such as perennial small grains, ecological weed management, intercropping for increased resilience, interseeding, rotational no-till practices, cover crop breeding and much more. Another large part of the lab is conducting farmer interviews to determine socioeconomic factors that influence the use of ecological farming practices. This is only a fraction of what we do and I cannot wait to share more throughout the rest of the summer.

Today I would like to talk about Hairy Vetch in our legume cover crop breeding trials, as well as my encounters with it in our perennial grain test plots. As I go home and explain my internship to my family who farms in Erie county, this piece of my internship always surprises them because Hairy Vetch is commonly known as a vigorous and competitive weed that you do not want to see in your fields. It can be serious problem, especially in fall sown small grains such as winter wheat. In our on-farm perennial grain test plots, I have seen a single plant spread out 4 feet in diameter. However, when used as a cover crop and intentionally seeded in early September, hairy vetch can overwinter and provide over 100 lb nitrogen per acre to subsequent crops planted in June. The competitiveness of hairy vetch is what makes it both a bad weed as well as a good cover crop. As a cover crop, it can smother weeds and reduce weed seed production; however, it can also smother crop plants and reduce yields when is it growing as a weed.

Our legume cover crop breeding project is a multi-site project, with sites in Maryland, North Carolina, Minnesota, and here in New York. We use traditional breeding techniques select for desirable traits. In addition to large amounts of biomass and vigor, some organic farmers are interested in early flowering and using hairy vetch for organic no-till production. This system involves mechanically killing the cover crop with a roller-crimper. Hairy vetch can be effectively killed without herbicides by rolling it when it is at the late flowering/early pod stage. Thus, organic farmers want early flowering varieties that will allow them to terminate the hairy vetch with a roller-crimper in May instead of June and no-till plant corn into the residue. Farmers are also very interested in reducing hard seededness (i.e., dormancy) in hairy vetch, as this trait leads to hairy vetch persistence in the soil seedbank and emergence at unwanted times such as during the wheat phase of a crop rotation.

My tasks in helping with the experiment included helping to trellis the plants, install deer fences, take meristem clips for DNA sequencing and eventually harvesting the seed pods.

Hard Cider, Hard Work

While the Orchards Store has many tasty apples and cider for sale, much of my work with apples this summer has been on something that the store does not offer–hard cider apple varieties. The Orchards has multiple plantings of apples that might not taste the best if picked right from the tree, but, if given time, will make excellent hard ciders. These apples can make a variety of cider tastes, as each have differing levels of volatile compounds. The apple varieties I have worked with come from all across the world, like England’s Dabinette, United Kingdom’s Brown Snout, and the United State’s Golden Russet. The newest apples at the Orchards are from Spanish varieties, and have been a long work in progress, as many new varieties have to be quarantined before they are allowed to be planted.

When I first arrived at the Orchards, the staff had recently planted a new block of cider apples. These apples are different than the previous cider plantings, because the new block was planted with Spanish style cider varieties like Blanquina Geneva and Raxao Geneva. These new varieties of apples will produce a different tasting style of beverage than what is currently sold on the market. Draft magazine calls the Spanish cider style “funky, tart, smoky and sometimes challenging ciders.” Cider is often measured in terms of tannin and acidity, and hard ciders are often categorized as bittersweet (high tannin, low acidity), bittersharp (high tannin, high acidity), sharp (low tannin, high acidity), and sweet (low tannin, low acidity), depending on the content of each volatile. The Spanish style hard cider is made from apples with different levels of tannins and acidity, and most varieties have high acidity levels. It has been fun to see the progression of a new planting, and all the work that goes into planting an apple field. I’m eager to come back in future years and see how the fruit tastes, and learn firsthand how different the Spanish style is from the current style that is popular in the United States. In the mean time, here is the work I have been doing on the new planting.

At first, the trees looked very small and weak in this open field, but not for long!

The Orchards staff and my fellow interns got to work building trellising for the trees, so they could stand up in Ithaca’s weather. The wooden posts were pounded in with a special machine, and will support the trees throughout their lifespan.

Next, we painted the tree trunks white to prevent winter freeze injury, and then added rubber bands and clips to keep the trees in place. We also marked a certain height on the tree with red paint, so staff can go back in and measure the diameter of the trunks for research projects.

In this picture, we are cutting tree guards to keep out rabbits and other animals during the winter months and prevent damage to the trees.

Lots of work goes into planting and maintaining trees, but I’ve enjoyed working hands on with the new planting!

Moisture sensors for remote irrigation monitoring

Over the past few weeks I have been able to work with an excellent new product for farmers using irrigation on crops. The CropX moisture sensor reads real time soil moisture and temperature. The best part about the CropX sensor is that through the app you can access your sensors data allowing you to make decisions on irrigation without being in the field. The sensors that I have been working with have the ability to give readings at depths of 8″ and 18″. This gives the ability to the grower to make decisions about when to irrigate his crop depending its rooting depth.

The sensor can be installed within minutes making it a very simple product to use. To activate the sensor you simply scan the qr code that is on the top of the sensor into the app. This the activates the sensor as well as pinning its location in the field in case you have trouble finding it.