Lindsay Fennell1, Shai Sela1, Aaron Ristow1, Harold van Es1, Shannon Gomes2

1Soil and Crop Sciences Section, School of Integrative Plant Science, Cornell University; 2Cedar Basin Crop Consulting

Determining the optimum nitrogen rate for corn production has been an elusive goal for many years, despite its economic significance to farmers and the concerns about environmental impacts. Several tools are available to provide nitrogen rate recommendations for corn growers, and many producers and retailers often wonder how these different recommendation systems compare. These approaches can be categorized as (i) static and (ii) adaptive. Static tools offer generalized recommendations that do not consider seasonal conditions of weather and soil/crop management, while adaptive approaches account for the variable and site-specific nature of soil N dynamics. Using strip trial data from four years of research on commercial farms we compare the recommendations from conventional static approaches in New York (Cornell Nutrient Calculator; CNC) and Iowa (Maximum Return to Nitrogen; MRTN) with the adaptive Adapt-N approach to explore the differences in recommended rates. The strip trials involved only Grower rates vs. Adapt-N rates as treatments, and we consequently cannot make direct conclusions on yield and profitability relative to CNC and MRTN. Therefore, in this article we focus on simply comparing the N rate recommendations from the three different tools.

The Tools

Cornell Nutrient Calculator: The Cornell Nutrient Calculator is a static approach that includes a basic mass balance calculation of N demand (yield-driven crop uptake) and N supply (soil organic matter, manure, previous crops, etc.), combined with efficiency factors. The CNC estimates can be derived from a spreadsheet downloaded from http://nmsp.cals.cornell.edu/software/calculators.html. The CNC nitrogen recommendation for corn is calculated as follows (Ketterings et al., 2003):

Where NRequired is the total amount of N (lbs N/acre) from any source required for optimum crop production. YPcorngrain is the yield potential of corn grain in bushels (85% dry matter) per acre. Nsoil and Nsod are the amounts of N (lbs N/acre) expected to be released from mineralization of soil organic matter and a plowed-down sod, respectively, and feff is a nitrogen uptake efficiency factor that depends on soil type and drainage. YPcorngrain, Nsoil, and feff are available from tabular values based on soil type that are incorporated into the spreadsheet. YPcorngrain can also be entered as a default value or based on field yield history. Manure contributions from up to three years past can be incorporated into the recommendations.

MRTN: The Maximum Return to N (MRTN) method is also a static approach which is based on the average economically optimum nitrogen rate (EONR) from multi-site and multi-year field trial data and is promoted in most Midwestern US states (Sawyer et al., 2006). In Iowa, MRTN recommendations are highly generalized into a single state-wide recommendation for either corn-after-corn or corn-after-soybean with adjustments only for the relative prices for grain and fertilizer. However, Deen et al. (2015) found that variations in seasonal weather were three times more impactful on EONR than price ratio fluctuations. MRTN recommendations can be determined using an online calculator (http://extension.agron.iastate.edu/soilfertility/nrate.aspx).

Adapt-N: The Adapt-N tool employs simulation models and biophysical data to combine soil, crop and management information with near-real-time weather data to estimate optimum N application rates for corn. Although it was developed at Cornell University it has recently been licensed for commercial use (adapt-N.com). It is currently calibrated for use on about 95% of the US corn production area and is flexible in terms of nutrient management options with inputs for applications of fertilizer or manure from different sources (dairy, swine, poultry), or rotation crops (sod, soybean, etc.). One of the key user inputs is the site-specific attainable yield, based on long-term yield records.

Adapt-N generates adaptive N recommendations based on a dynamic mass balance approach according to the following equation:

Where Nrec is the N rate recommendation; Nexp_yld is the crop N content needed to achieve the expected yield. The expected yield is based on producer provided historic field data; Ncrop_now and Nsoil_now are the N content in the crop and soil as calculated by the model for the current simulation date; Nfut_gain-loss is a probabilistic estimate of future N gains minus losses until the end of the growing season, based on model simulations with historical rainfall distribution functions; and Nprofit_risk is an economic adjustment factor that integrates corrections for fertilizerand grain prices, as well as the relative profit risk of under-fertilization vs. over-fertilization.

Adapt-N vs. Cornell N Calculator and MRTN rates

Adapt-N was used in 115 paired field strip trials with three or four nitrogen fertilizer replications conducted mostly on commercial farms (two university research farms were involved) in New York and Iowa during the 2011-through-2014 growing seasons (cf. Fennell et al., 2015; this issue). Although the experimental design of the study compares N rates for Adapt-N and Grower-selected treatments (which represented conventional practices), we also had an opportunity to compare the adaptive approach of the Adapt-N tool to the respective rates recommended by the CNC and the MRTN methods. Note: Each growing season did not necessarily involve the same fields and management practices, like manure application. The pre-plant or starter fertilizer rates varied and averaged 76 and 56 lbs/ac for the NY and IA trials, respectively.

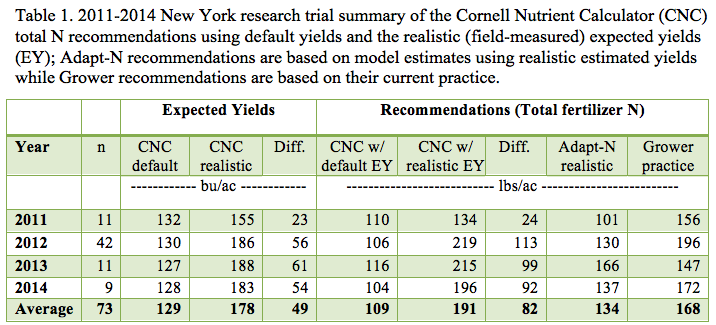

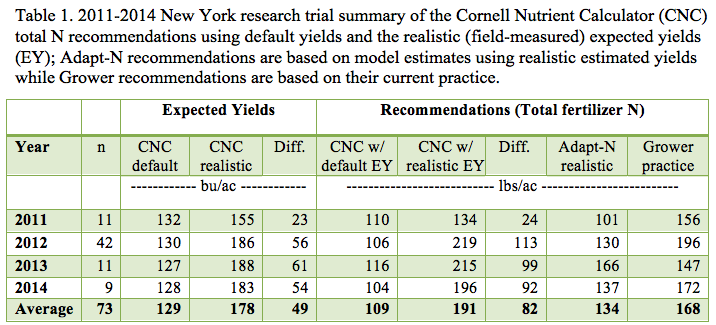

The CNC estimate included two rates: (i) based on the default yield potentials in the CNC software (which were universally much lower) and (ii) based on expected yield values for the field supplied by the grower, i.e. “realistic” field-specific expected yield. N credits from manure application were directly accounted for in the CNC software.

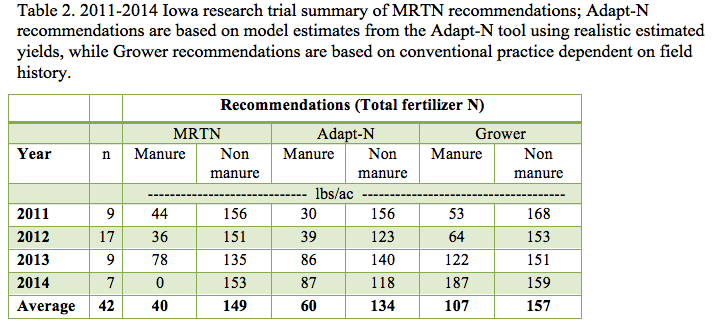

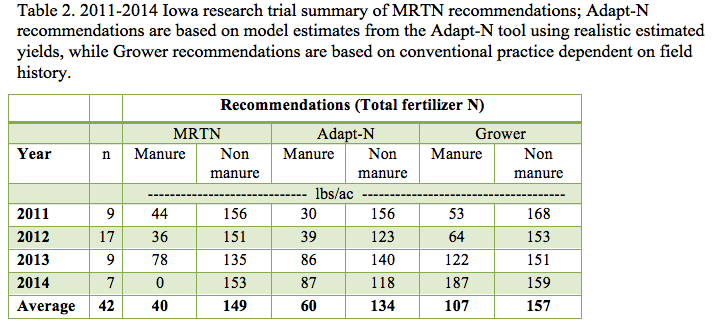

For the MRTN approach, the rate was adjusted to account for manure credits calculated using the Iowa State University manure management guidelines (PM-1811), which assumes N use efficiency of 100% and 35% for swine and dairy manure, respectively. If the sum of the calculated credits for a trial exceeded the MRTN rate, a zero MRTN rate was assigned.

Results

In contrast to the static N recommendation approach, Adapt-N recommended N rates varied substantially from field to field and among growing seasons (Table 1 and 2). Since the strip trials involved an Adapt-N and a Grower-selected rate, they allow us to make conclusions on the performance of these two approaches. In short, results showed that in 83% of all 115 strip trials, Adapt-N recommended a lower N application than the respective Grower-defined rate and these reduced rates resulted in an increased profit in 73% of trials, with an average increase of $29/ac over the Grower rate (Sela et al., in review; Moebius-Clune et al., 2014).

CNC vs. Adapt-N: The CNC method accounts for several variables, including past manure applications and soil types, which, as previously mentioned, are reflected in a different rate for each trial. One issue with the current CNC approach is the selection option for the yield potential (YP), based either on default values or “realistic” yield estimates from historic field-measurements. The CNC default expected yields were on average 49 bu/ac lower than the realistic expected yields (Table 1). Incidentally, New York grower-estimated realistic yields averaged 178 bu/ac, which was generally close to the actual achieved yields at the end of the season, 173 bu/ac on average. The resulting CNC N rate recommendations were highly sensitive to these yield estimates: rates based on realistic yields averaged 82 lbs/ac higher than those based on the default expected yields (191 and 109 lbs/ac, respectively).

Adapt-N recommended rates fell in between those extremes at 134 lbs/ac. (Table 1, Fig. 1a). I.e., the CNC rates calculated using the realistic estimated yields were on average 57 lbs/ac higher than the Adapt-N rates. Based on the results of the comparison of Adapt-N with Grower-selected rates (which were generally excessive but still 23 lbs/ac lower than the CNC rates with realistic yields; Table 1), we infer that the CNC recommendations with realistic expected yields are generally too high. Conversely, using the less-realistic default yields appears to result in overall better N rate recommendations, but still too low in wetter seasons (esp. 2013).

Adapt-N recommended rates fell in between those extremes at 134 lbs/ac. (Table 1, Fig. 1a). I.e., the CNC rates calculated using the realistic estimated yields were on average 57 lbs/ac higher than the Adapt-N rates. Based on the results of the comparison of Adapt-N with Grower-selected rates (which were generally excessive but still 23 lbs/ac lower than the CNC rates with realistic yields; Table 1), we infer that the CNC recommendations with realistic expected yields are generally too high. Conversely, using the less-realistic default yields appears to result in overall better N rate recommendations, but still too low in wetter seasons (esp. 2013).

MRTN vs. Adapt-N: The MRTN rates for the Iowa trials were fixed at 188 lbs/ac and 133 lbs/ac for corn-after-corn and corn-after soybean rotations, respectively for the non-manured sites (Fig 1b), while the Adapt-N rates showed a wide range from about 40 to 220 lbs/ac, primarily depending on soil type, organic matter contents and weather conditions. On average the Adapt-N rates for non-manured sites were 15 lbs/ac lower than the respective MRTN rates (134 vs.149 lbs/ac; Table 2).

The Iowa manured sites showed a wide range of fertilizer recommendations for both Adapt-N and MRTN (Fig 1b). On average, the recommended fertilizer rates for Adapt-N were 20 lbs/ac higher than MRTN, with differences especially pronounced in cases involving fall swine manure applications where the Iowa State University calculations assume 100% N contribution for the following growing season, often resulting in very low N fertilizer recommendations. The Grower practice averaged higher than both the MRTN rates and Adapt-N rates, especially for manured fields (67 and 47 lbs/ac higher than MRTN and Adapt-N, respectively). In all, MRTN rates are similar on average to Adapt-N rates, but the former is lower with manure applications and higher without manure. Adapt-N rates varied more based on location-specific conditions.

Conclusions

The static N recommendation tools are more generalized compared to adaptive tools like Adapt-N, and do not allow for precision N management specific to each production environment (field, season, management). The 115 strip trials offered an opportunity to make comparisons of Adapt-N with Cornell N Calculator (New York) and MRTN (Iowa) N rate recommendations under real-farm conditions, but did not enable direct analysis of their relative yield and profitability performance.

We conclude that the main issue with the CNC recommendations is the large discrepancy between the N recommendations using the default yield potentials and those based on realistic yield potentials. When using the latter, the yield expectations are more correct but the recommended rates are much higher than the Adapt-N rates and appear to be excessive in most cases. Conversely, recommendations based on default yields average below Adapt-N rates and appear to be too conservative in wetter years. The default yield values appear to be about 40-50 bu/ac below current yields, which have in recent decades increased due to improved crop genetics and management. Updating the default yield values appears logical, but would result in excessive N recommendations in most years.

MRTN recommended rates were on average similar to Adapt-N rates, but they were lower with manure applications and higher without manure. In the non-manure cases, MRTN rates were principally higher in some years (2012; 2014). Adapt-N rates varied more based on location-specific conditions, which is important for preventing excesses and deficiencies and reducing environmental impacts.

In all, we conclude that on average the static (CNC and MRTN) and adaptive (Adapt-N) approaches resulted in similar N rate recommendations, but they vary considerably depending on growing season weather, soils, management practices and yield assumptions.

Acknowledgements

This work was supported by funding from the USDA-NRCS Conservation Innovation Program grant number 1258410, New York Farm Viability Institute, USDA-NIFA WQ grant number 1258250, the Northern New York Agricultural Development Program, USDA-Sustainable Agriculture Research and Extension grant number 1258396, the International Plant Nutrition Institute, and the McKnight Foundation. We are grateful for the cooperation in field activities from Keith Severson, Sandra Menasha, Anita Deming, and Michael Davis of Cornell Cooperative Extension, David DeGolyer, Dave Shearing and Jason Post of Western NY Crop Management Association, Eric Bever and Mike Contessa at Champlain Valley Agronomics, Eric Young at Miner Institute, Peg Cook of Cook’s Consulting, and Hal Tucker, Michael McNeil, and Frank Moore of MGT Envirotec. We also are thankful for the cooperation of the many farmers who implemented these trials on their farms.

References

Deen, B., K. Janovicek, J. Lauzon, and T. Bruulsema. 2015. Optimal rates for corn nitrogen depend more on weather than price. Better Crop. with Plant Food 99(2): 16–18.

Fennell, L., S. Sela, A. Ristow, B. Moebius-Clune, D. Moebius-Clune, R. Schindelbeck, and H. van Es. 2015. Adapt-N Recommendations Reduce Environmental Losses. What’s Cropping Up? 25: (this issue).

Ketterings, Q.M., S.. Klausner, and K.J. Czymmek. 2003. Nitrogen guidelines for field crops in New York. CSS Extension Series E03-16. Cornell University, Department of Crop and Soil Sciences, Ithaca NY. 70 pp.

Moebius-Clune, B., M. Ball, H. van Es, and J. Melkonian. 2014. Adapt-N Boosts Profits and Cuts N Losses in Three Years of On-Farm Trials in New York and Iowa. What’s Cropping Up? 24:57-60.

Sawyer, J., E. Nafziger, R. G., L. Bundy, G. Rehm, and B. Joern. 2006. Concepts and rationale for regional nitrogen guidelines for corn. PM 2015. Iowa State Univ. Ext., Ames, IA.

Sela., H.M. van Es, B.N. Moebius-Clune, R. Marjerison, J.J. Melkonian, D. Moebius-Clune, R. Schindelbeck, and S. Gomes, Adapt-N Recommendations for Maize Nitrogen Management Increase Grower Profits and Reduce Environmental Losses on Northeast and Midwest USA Farms, Submitted to the Soil Science Society of America Journal.

van Es, H.M., B.D. Kay, J.J. Melkonian, and J.M. Sogbedji. 2007. Nitrogen Management Under Maize in Humid Regions: Case for a Dynamic Approach. p. 6–13. In Bruulsema, T. (ed.), Managing Crop Nutrition for Weather. International Plant Nutrition Institute.