Biomaterials & Biointerfaces in Food & AgricultureMaterials are used to handle, process, and package our food at many stages from farm to fork. The goal of the Goddard research program on Biomaterials and Biointerfaces is to leverage technologies at the intersection of Food Science and Materials Science to modify these food contact materials to improve the quality, safety, and sustainability of our food supply.

Goals and opportunities in this field include design of coatings and materials which improve food quality (e.g. packaging materials that enable removal of synthetic additives with retention of product shelf life), sustainability (e.g. bioprocessing materials to improve efficiency and environmental sustainability), and food safety (e.g. cost effective, durable antimicrobial coatings).

Antimicrobial and Non-Fouling Coatings

Materials with antimicrobial or non-fouling character have application in improving public health, reducing energy consumption, and mitigating food waste, among others. Significant research has been published on techniques in surface modification that prevent protein conditioning and subsequent microbial attachment (non-fouling), inactivate adhered microorganisms (antimicrobial) or facilitate biofilm removal (self-cleaning). In this research thrust, we design, synthesize, and demonstrate practical efficacy of hybrid antimicrobial & non-fouling coatings in inhibiting microbial adhesion and biofilm formation, inactivating those that do adhere, and promoting more facile removal of established biofilms.

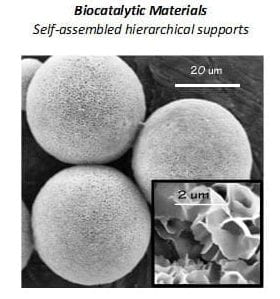

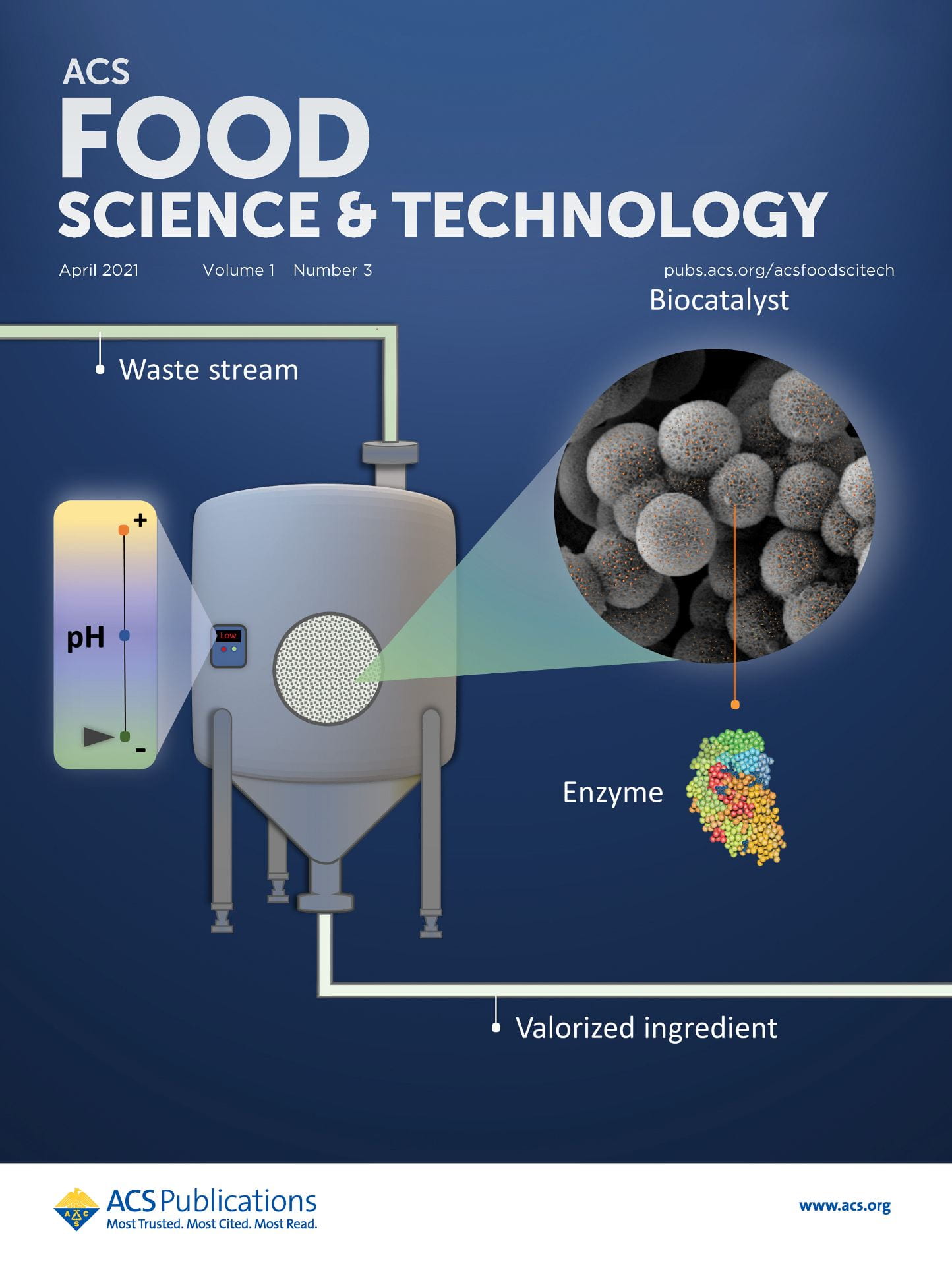

Biocatalytic MaterialsEnzyme mediated catalysis offers several advantages over traditional catalysts due to improved specificity, reduced by-product formation, and recyclability.

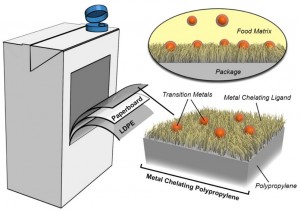

The goal of this research area is to utilize materials to immobilize, stabilize, and/or facilitate recovery of enzymes used in active packaging and bioprocessing and to understand how engineering enzymes with unique molecular features can improve their performance in non-ideal conditions. Through this research program, we explore both fundamental and applied research hypotheses, from understanding the influence of nanoparticle size on the recovery and activity retention of immobilized enzymes to demonstrating the impact of biocatalytic packaging films on milk quality.

Active Packaging |

Goddard group research is supported by USDA National Institute of Food and Agriculture (USDA NIFA), National Institutes of Health (NIH), National Science Foundation (NSF), and Foundation for Food & Agriculture Research (FFAR).

The Goddard group has synthesized polymers with specific biological functionality (e.g. enzymatic, antimicrobial/nonfouling, chelating) targeting applications in Food Packaging, Bioprocessing Materials, and Equipment Coatings.

The Goddard group has synthesized polymers with specific biological functionality (e.g. enzymatic, antimicrobial/nonfouling, chelating) targeting applications in Food Packaging, Bioprocessing Materials, and Equipment Coatings.

Employing these powerful nanoscale biocatalytic materials to perform highly specific reactions enables significant advances in value-added processing of agricultural waste, development of biocatalytic active packaging materials, and lab-on-a-chip reactors.

Employing these powerful nanoscale biocatalytic materials to perform highly specific reactions enables significant advances in value-added processing of agricultural waste, development of biocatalytic active packaging materials, and lab-on-a-chip reactors.