Take advantage of the below spring workshop offerings and plan your training for the year by checking out our online course calendar. In addition to our these upcoming workshops, our Dairy Science and Sanitation, HACCP, and Vat Pasteurization courses are fully online with rolling admission. For questions related to these workshops, registration, or facility training options, please reach out to Louise Felker at LMF226@CORNELL.EDU

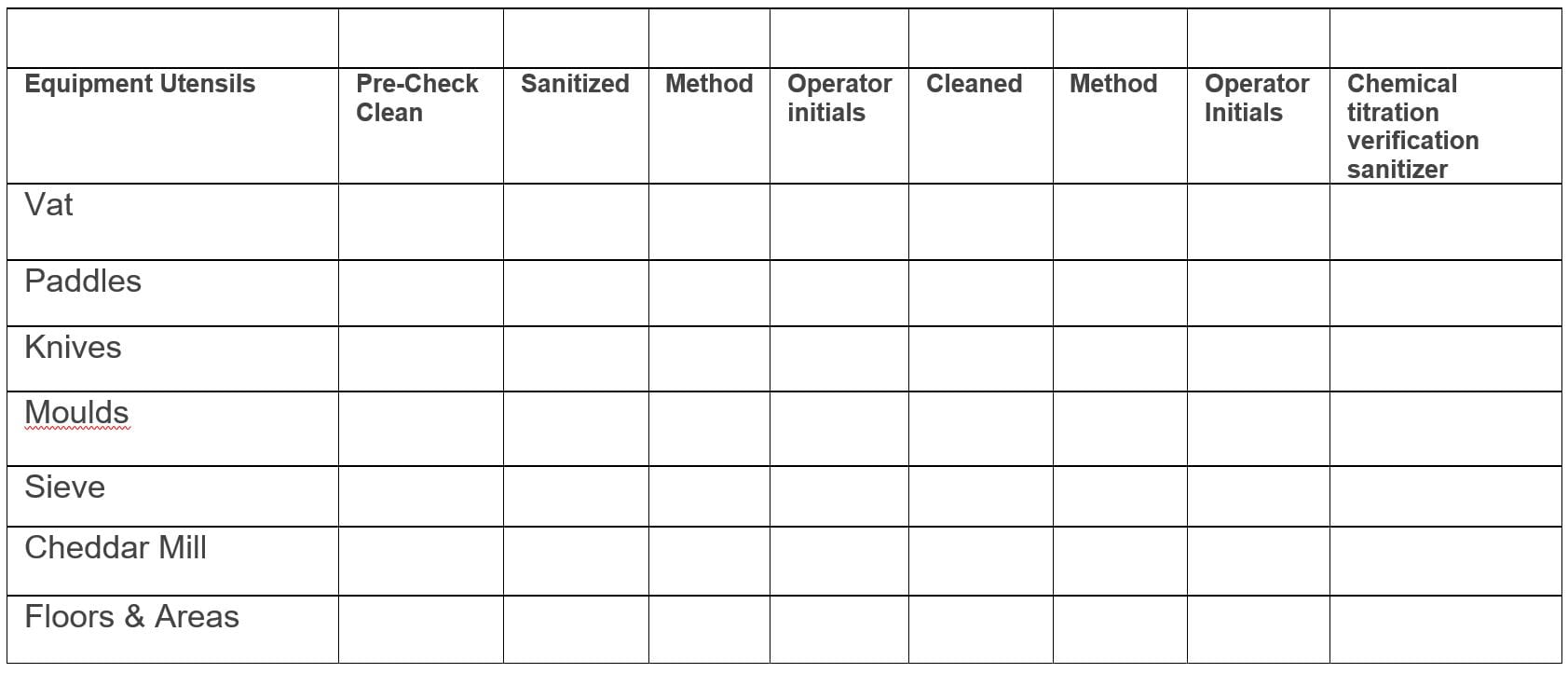

Open now, Limited Space Available: The Science of Cheese– The Science of Cheese workshop is designed for cheese manufacturers or others interested in the basic concepts of cheese making. The online session is available beginning March 24, 2021, and the live video conference session will be held on April 21, 2021. This course covers cheese culture basics, raw milk quality, cheese defects, cleaning and sanitizing, affinage, food safety, basic cheese making techniques, a virtual cheese make, and sensory evaluation. Cheese samples for evaluation will be shipped to each participant’s location.

Opens April 12th: The Science of Yogurt– The workshop will provide participants with information in key areas related to milk quality and its impact on finished dairy products, product evaluation and defects, ingredients in cultured dairy products, and product processing and formulation. Online lectures are available beginning April 12th with an instructor-led virtual session on May 11th.

April 13th-15th: HTST Pasteurizer Workshop– All required regulatory tests for HTST pasteurizers will be discussed and presented in a hands-on format to meet the training requirements for performing HTST system testing under the NY State Broken Seal Policy. Additional topics include UHT systems, dairy microbiology, product safety, and cleaning and sanitizing. This workshop will be held virtually.

April 20th: Dairy Lab Seminar– This 4-hour online seminar provides dairy laboratory personnel with regulatory, procedural and scientific updates This program is designed for those actively working in dairy product testing and quality assurance programs, but may be of interest to Certified Milk Inspectors, plant receivers, and other plant personnel

May 12th-14th: Preventive Controls for Human Food– This instructor-led online course will fulfill the FDA Requirements for FSMA Qualified Individual Training through the Food Safety Preventive Controls Alliance and AFDO. The course will include opportunities for participants to review the final rule and participate in classroom exercises to better understand the regulation. At the conclusion of the course, participants will receive a certificate issued by the Association of Food and Drug Officials (AFDO) certifying their training as a Preventive Controls Qualified Individual.

some University Professor’s political opinion piece, it’s a question about the state of your business. At home you might be getting comfortable using your iPhone to track your daily exercise, or asking Alexa to dim the living room lights, but what happens when you get to your dairy facility? Some of you might be nodding knowingly and others suspiciously.

some University Professor’s political opinion piece, it’s a question about the state of your business. At home you might be getting comfortable using your iPhone to track your daily exercise, or asking Alexa to dim the living room lights, but what happens when you get to your dairy facility? Some of you might be nodding knowingly and others suspiciously.