Three weeks ago, I started my internship working for the Nutrient Management Spear Program (NMSP) in Cornell’s Animal Science Department, run by Dr. Quirine Ketterings. The main goal of the program is to aid farms (focusing on dairy farms) to become more sustainable. The team does this by conducting a variety of research—both on farm and at experiment farms, lab work, and through Cooperative Extension outreach. The research evaluates numerous soil management practices and their effect on the farm’s sustainability by looking at the amount of farm inputs vs. the products exported from it. Some of the management methods under review include: crop rotations, manure application, fertilizer application, yield monitor accuracy, and tillage.

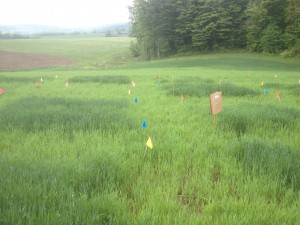

My first week was largely assisting with a project examining the effect of different nitrogen fertilizer application rates on triticale and wheat fields. This project will be looking at the differences in yield as well as the nutrient content of forages. Pictured left are different levels of application on each plot and the distinction from the rest of the field. Once samples are harvested by hand, we take them back to the lab to be weighed when they are wet and then dry after three days in the oven. Once this is done, the samples are put through a grinder and prepared for nutrient analysis.

My first week was largely assisting with a project examining the effect of different nitrogen fertilizer application rates on triticale and wheat fields. This project will be looking at the differences in yield as well as the nutrient content of forages. Pictured left are different levels of application on each plot and the distinction from the rest of the field. Once samples are harvested by hand, we take them back to the lab to be weighed when they are wet and then dry after three days in the oven. Once this is done, the samples are put through a grinder and prepared for nutrient analysis.

In week two I assisted with a project evaluating the accuracy of yield monitors on choppers. This project evaluates the monitor accuracy of crop moisture content and the necessary frequency of monitor calibration. To do this, the chopper operator is given a sheet to record what the yield monitor reads for moisture content for each load of alfalfa. Samples are then taken from each load and dumped at the bunk (pictured left). They are then weighed to determine actual crop moisture content.

In week two I assisted with a project evaluating the accuracy of yield monitors on choppers. This project evaluates the monitor accuracy of crop moisture content and the necessary frequency of monitor calibration. To do this, the chopper operator is given a sheet to record what the yield monitor reads for moisture content for each load of alfalfa. Samples are then taken from each load and dumped at the bunk (pictured left). They are then weighed to determine actual crop moisture content.

In week three, I received my summer research project. I will continue work with an on-going study comparing varying depths of zone tillage looking at differences in yield and soil quality. I will start with a farm visit that has been aiding in this research, and will include the details in my next post!